Crofer 22H M_Grid™

for effective current collection

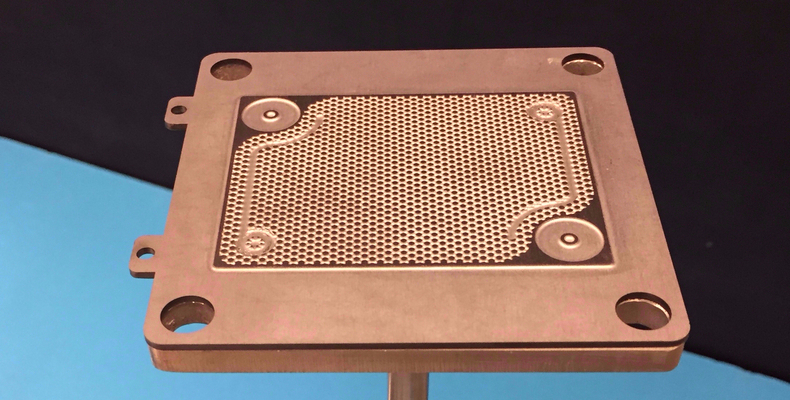

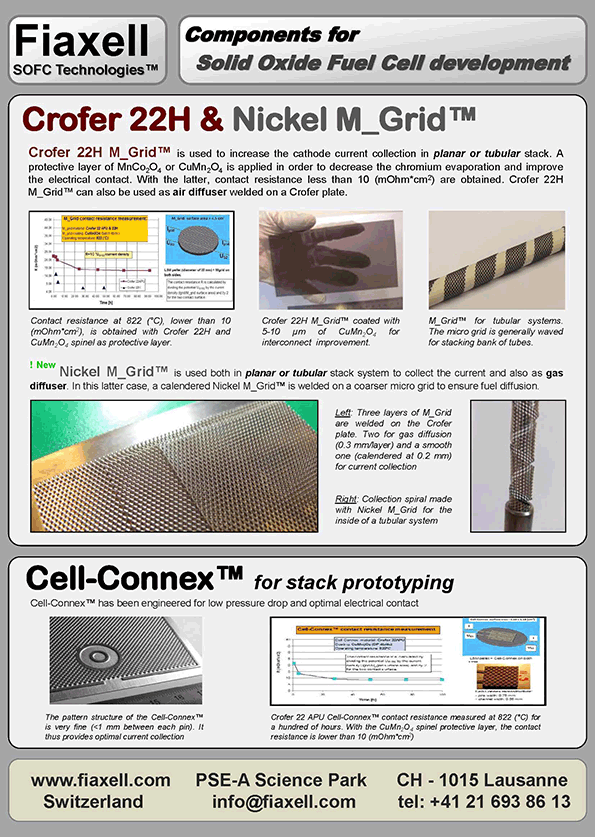

Crofer 22H M_Grid™ coated with 5-15 µm of CuMn2O4 spinel for current collection improvement on the air side of the interconnectLow contact resistance:

Crofer 22H M_Grid™ coated with 5-15 µm of CuMn2O4 spinel for current collection improvement on the air side of the interconnectLow contact resistance:

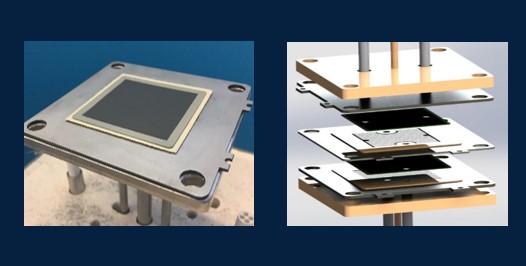

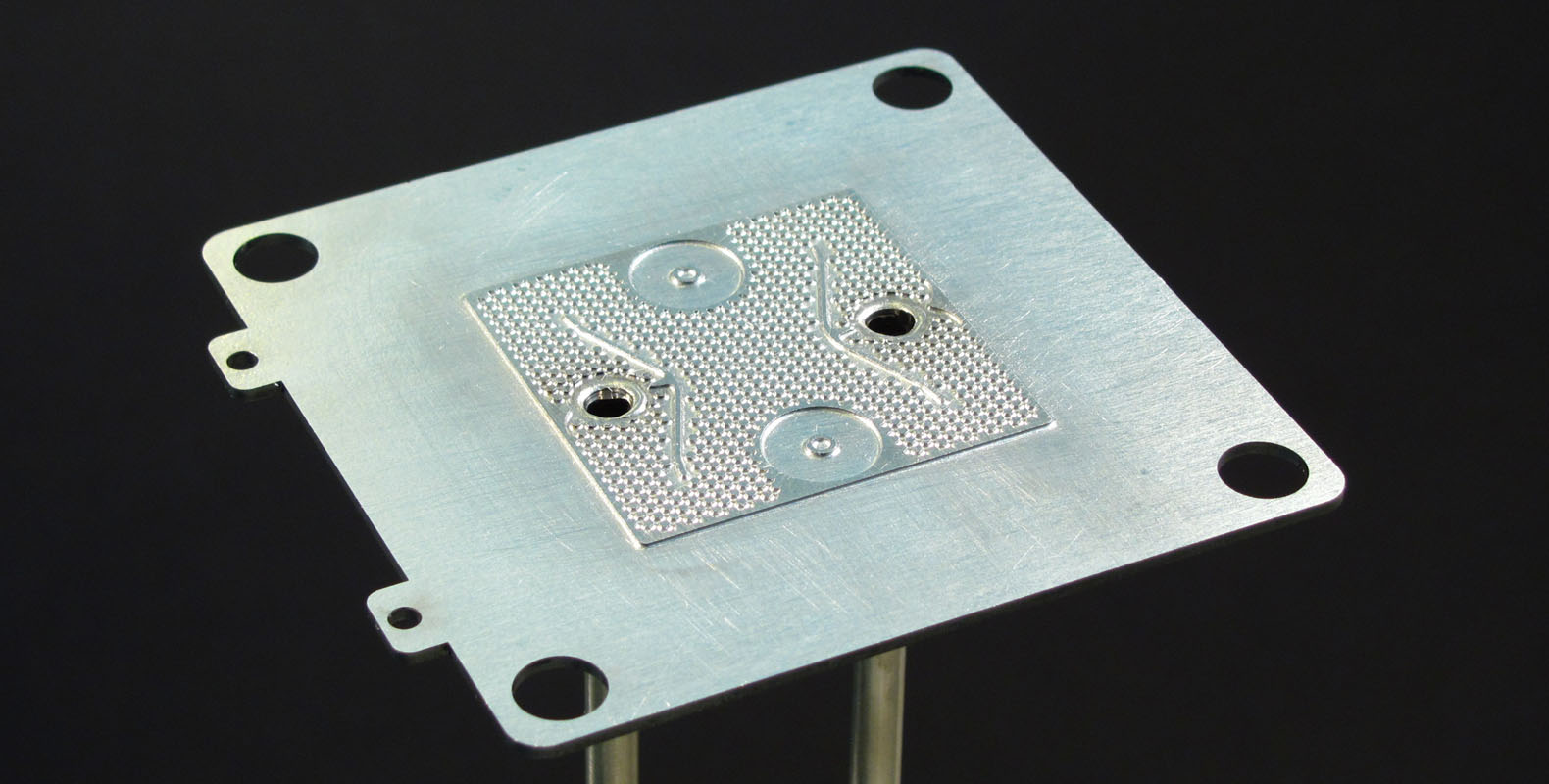

Crofer 22H M_Grid™ has been designed to improve the cathode current collection in planar or tubular stack

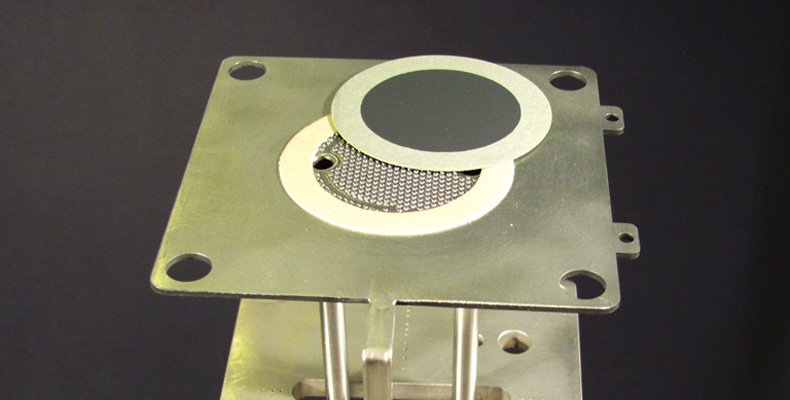

Spinel coated:

A protective layer of MnCo2O4 or CuMn2O4 is applied in order to decrease the chromium evaporation and improve the electrical contact

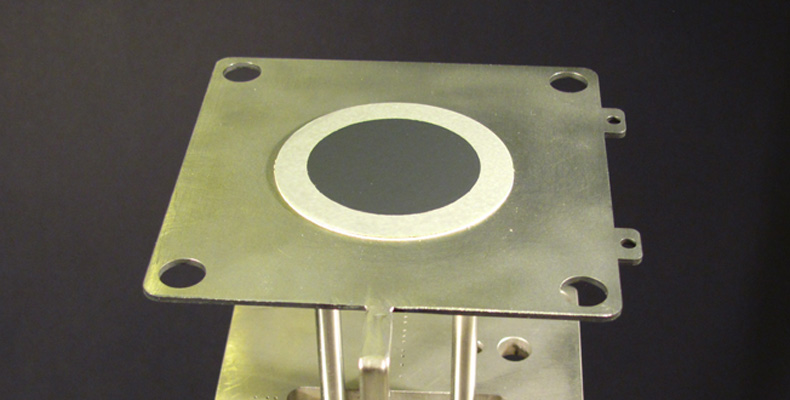

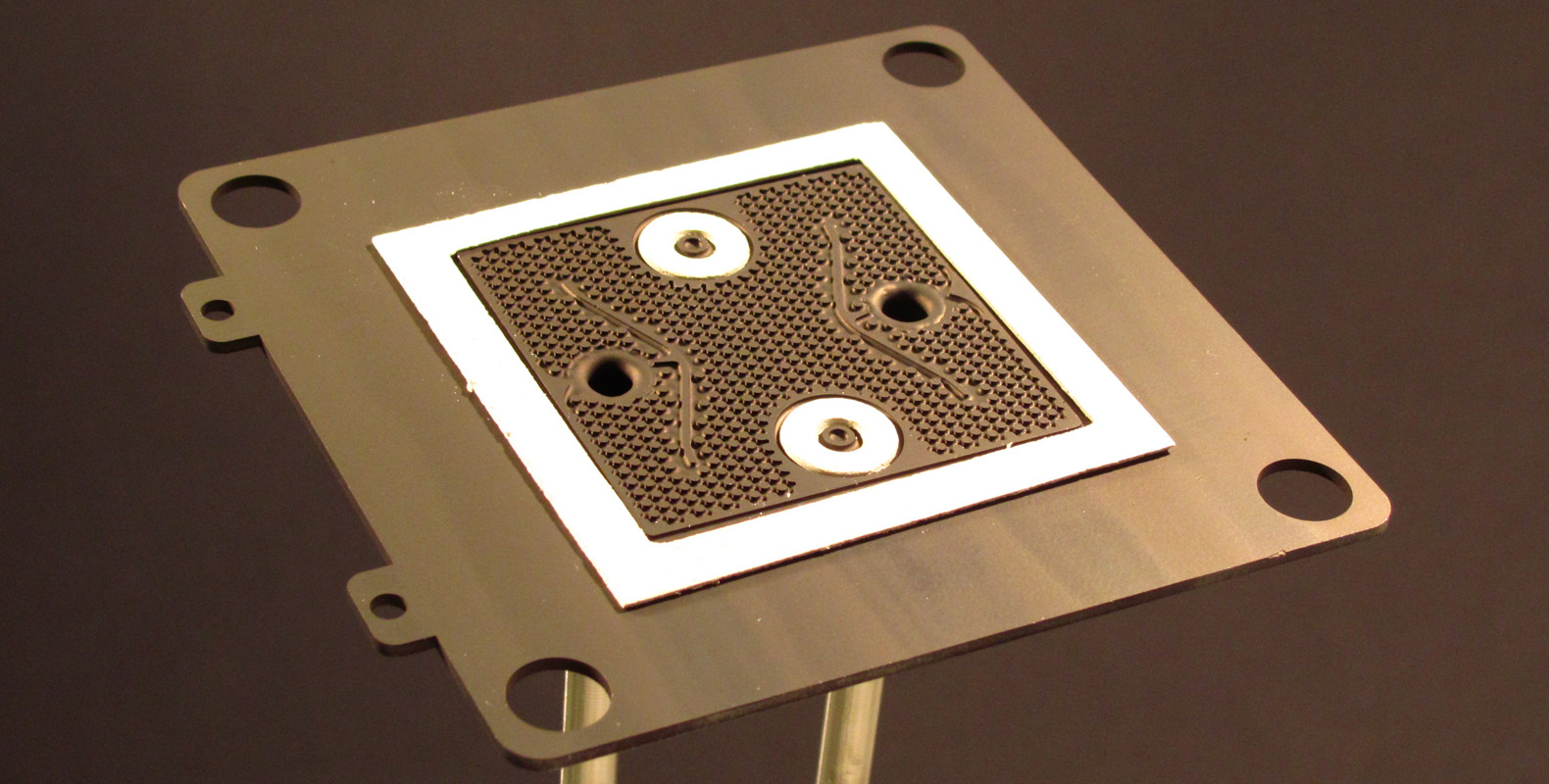

Gas diffuser:

In order to create a 3D structure for gas diffusion, a sandwich of calendered and nominal M_Grid™ are welded on the Crofer plate

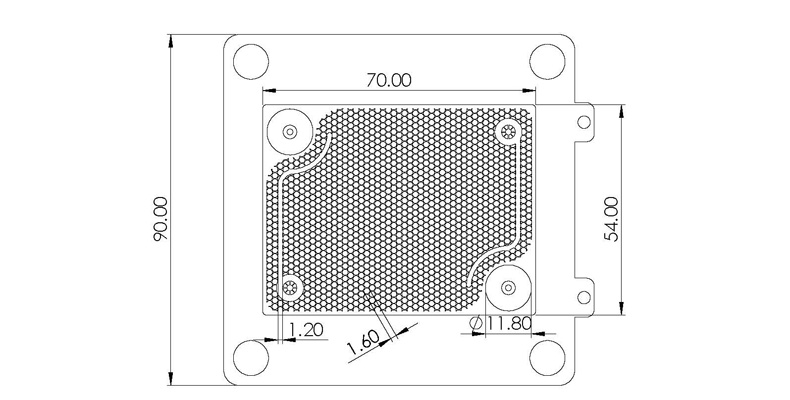

Crofer 22H M_Grid™ specifications:

Crofer 22H M_Grid™ with 5-15 µm of CuMn2O4 spinel coating- Material: Crofer 22H

Crofer 22H M_Grid™ with 5-15 µm of CuMn2O4 spinel coating- Material: Crofer 22H

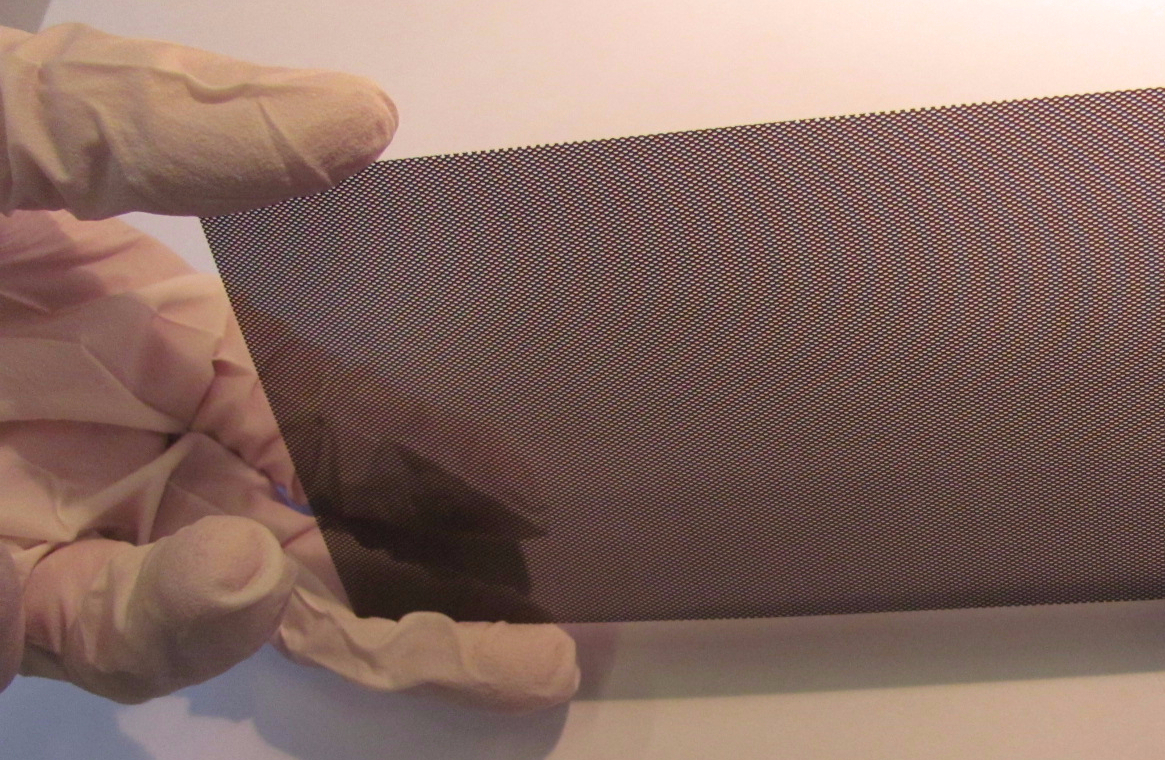

- Mesh opening: 1.4 X 0.9 mm (diagonals)

- Maximum width/length: 130 mm/1200 mm

- Thickness after calendering: 0.2 mm

- Standard coating: 5-15 µm of CuMn2O4 spinel (other material on request)

- Proprietary coating to prevent any gas cracking for direct CH4 or CO feeding

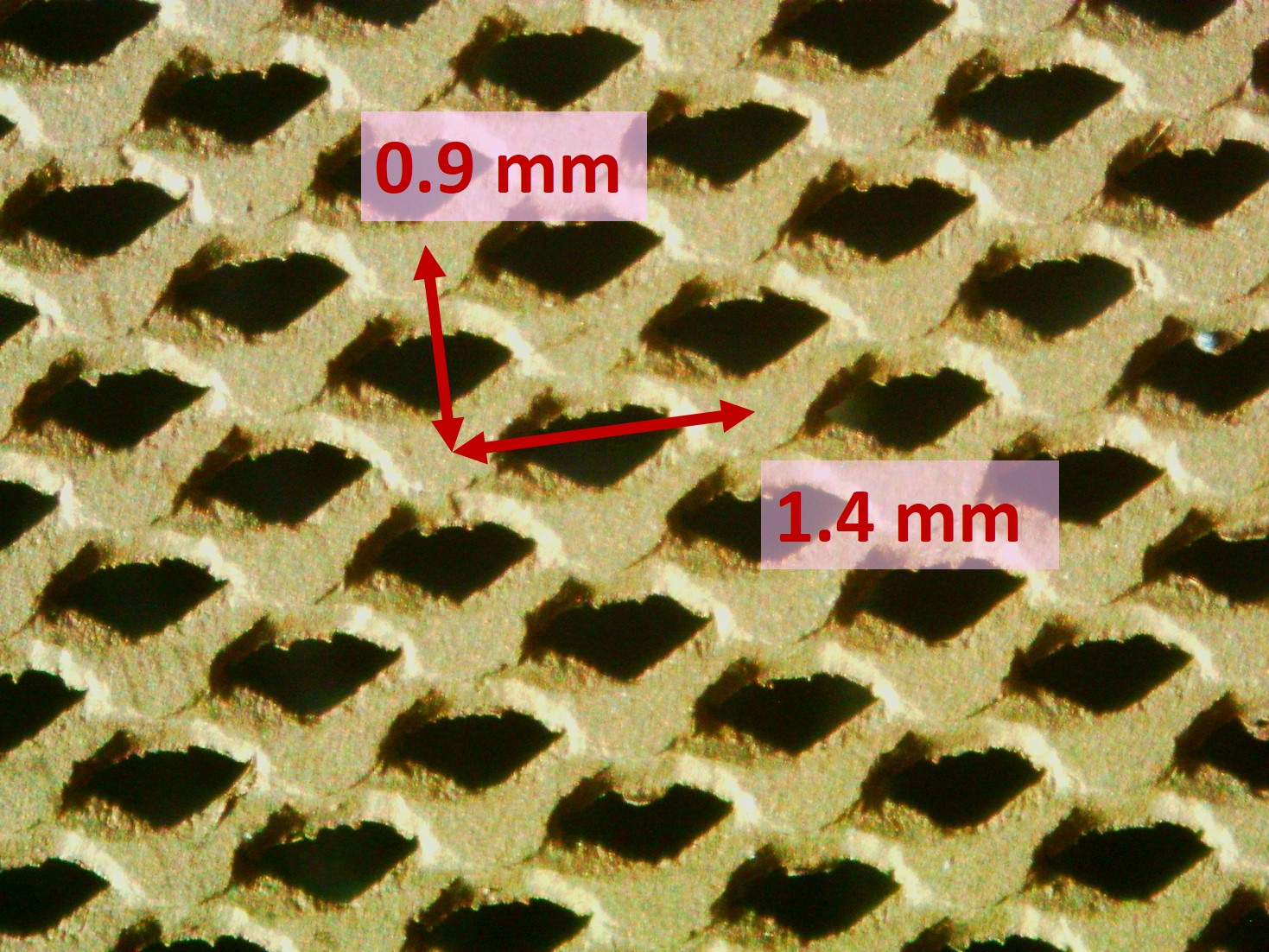

Crofer 22H M_Grid™ contact resistance:

Ohmic resistance in function of time has been measured for Crofer 22APU and Crofer 22H M_Grid™. The measurements have been carried out with two same M_Grid on both side of a LSM pellet. Resistance of less than 10 mOhm*cm2 have been measured at 820 °c for Crofer 22H M_Grid™.

Ohmic resistance of Crofer 22APU and Crofer 22H M_Grid™ with 5-15 µm of CuMn2O4 spinel coating

Ohmic resistance of Crofer 22APU and Crofer 22H M_Grid™ with 5-15 µm of CuMn2O4 spinel coating

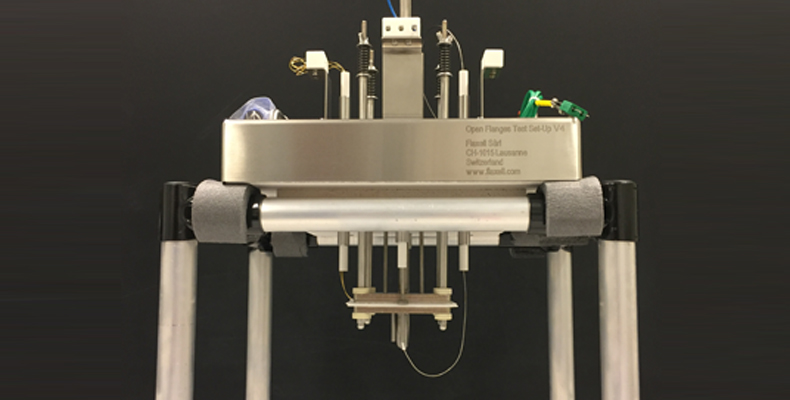

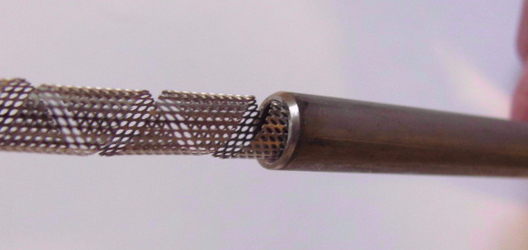

M_Grid™ for tubular system:

M_Grid™ made of Crofer 22H and other non noble materials such as nickel can be advantageously used in tubular system. As shown below, internal or external current collection is achieved by spiraling the M_Grid™ inside or outside the tube. The M_Grid™ can also be formed to receive directly the tubular cells in a rounded shape.

External current collection: The Crofer 22H M_Grid™ is rolled on the tube.

External current collection: The Crofer 22H M_Grid™ is rolled on the tube.  Internal current collection: the nickel M_Grid is spiraled inside the tube

Internal current collection: the nickel M_Grid is spiraled inside the tube Download the brochure:

Click on the picture to download the brochure or click here to go to all Fiaxell brochures