Multi-Flanges™ testing rig (4-MF™)

One single setup, four SOFC/SOEC cells tested in a run

As manufacturer and supplier of SOFC / SOEC components, Fiaxell is now proposing a new test fixture, the Multi-Flanges™ that allows to test 4 cells simultaneously and independently. As for the Open-Flanges™, this new test rig cumulates the following advantages (see also table below for comparison):

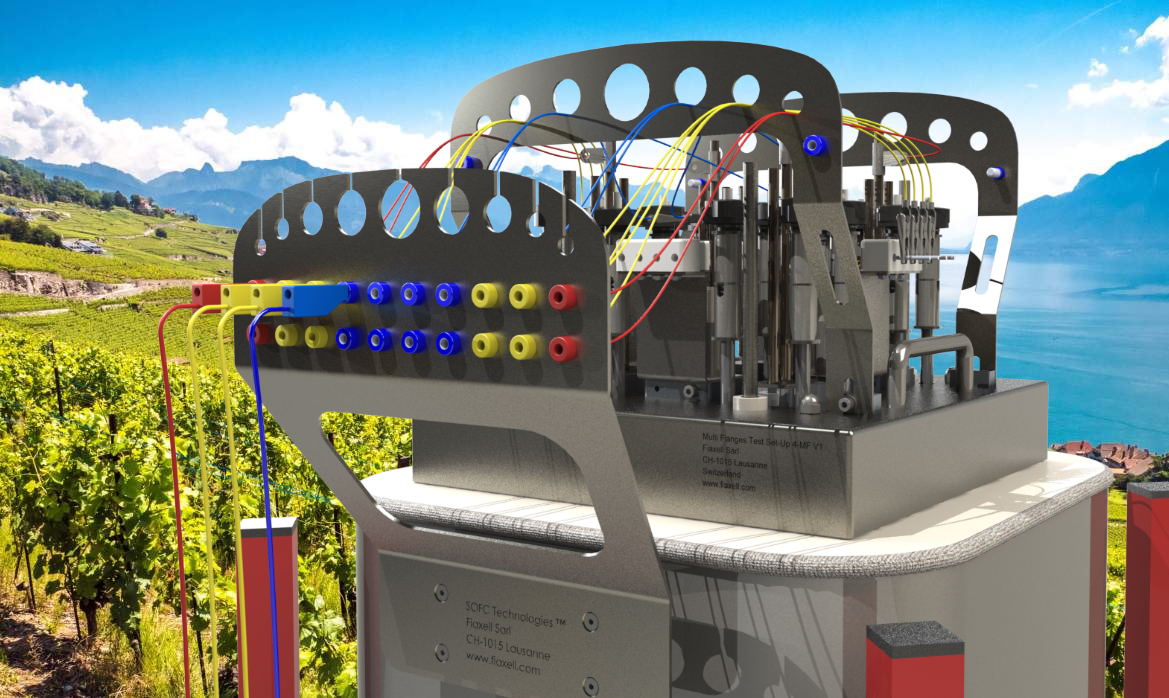

The Multi-Flanges™ test fixture in its furnace. It is an ideal testing device for intensive SOFC / SOEC cell measurements

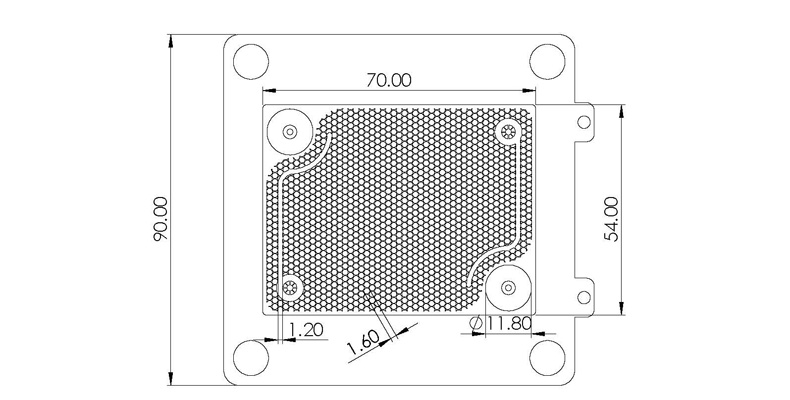

The Multi-Flanges™ test fixture in its furnace. It is an ideal testing device for intensive SOFC / SOEC cell measurementsFlexible cell dimensions and shape: from one to the other experiment, small pellet to medium size circular (max. ∅ 40 mm) or square cell (max. 30 X 30 mm) can be installed in the SOFC / SOEC Multi-Flanges™ button cell test stand.

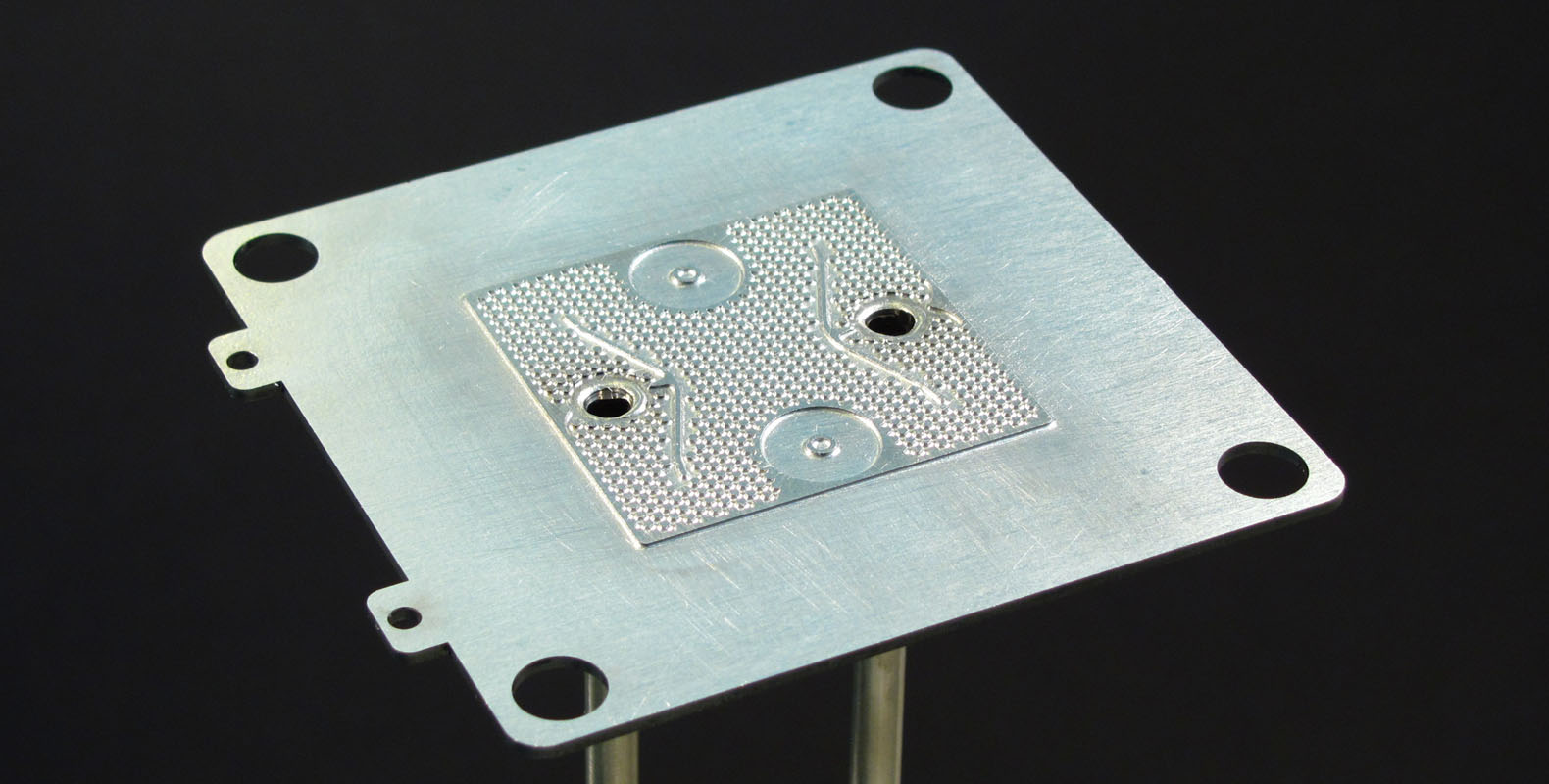

Quick start of experiment: As for the Open-Flanges™ test Set-Up, the cell mounting is very fast. A "quick spring compression" mechanism has been implemented in order to ensure a pre-defined pressure on all the four cells without spring length measurement

Open flanges or gas recovery:: Thanks to its proprietary head design, the Multi-Flanges™ SOFC / SOEC test station allows button cell testing with or without gasket (open flange test mode or with exhaust gas recovery)

Ideal or real testing conditions:: The Multi-Flanges™ test stand allows for testing both electrodes (fuel and air) in ideal or real conditions. Stainless steel terminal such as Cell-Connex™ can replace nickel diffuser and/or gold M_Grid™ generally used for ideal measurements

Long term testing: Long term test can also be run in the Multi-Flanges™ test fixture. The alumina housing on air side allows to prevent any poisoning (Cr, Ni etc.) as it can be seen in details on the long term test kit dedicated web page

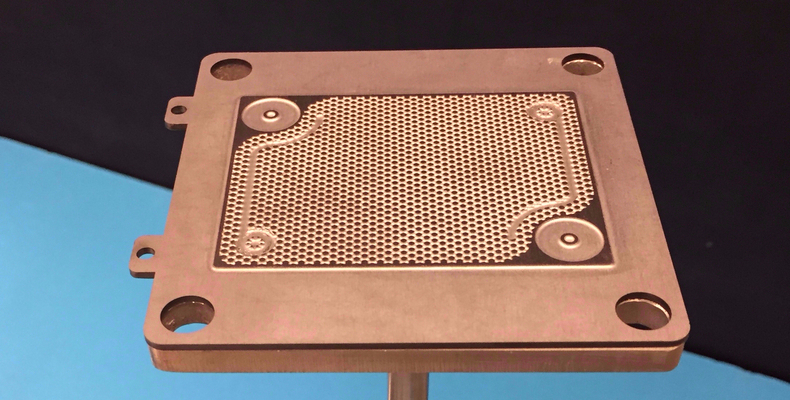

Other SOFC components: the Multi-Flanges™ test rig is also useful for measurements of other components such as: SOFC / SOEC electrolyte & electrode material, interconnect, spinel protective coating, tightness of sealant materials (glass, mica gold ring etc.)

End of broken cells: fragile and un-perfect cells can also be mounted in the SOFC / SOEC Multi-Flanges™ test rig heads. In this case, the cell is squeezed between soft alumina felts that prevents any damages. Quick made lab prototype cells (ASC / ESC) can thus be directly evaluated in the SOFC / SOEC Multi-Flanges™ button cell tester before material improvement

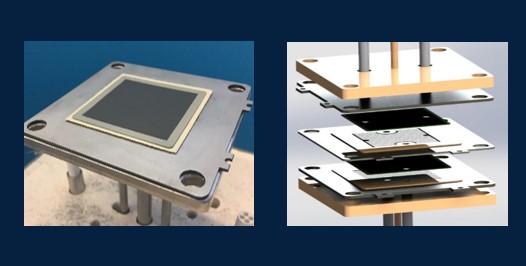

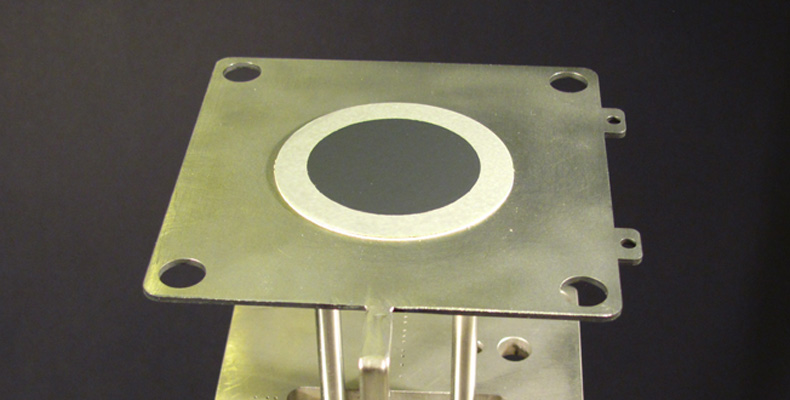

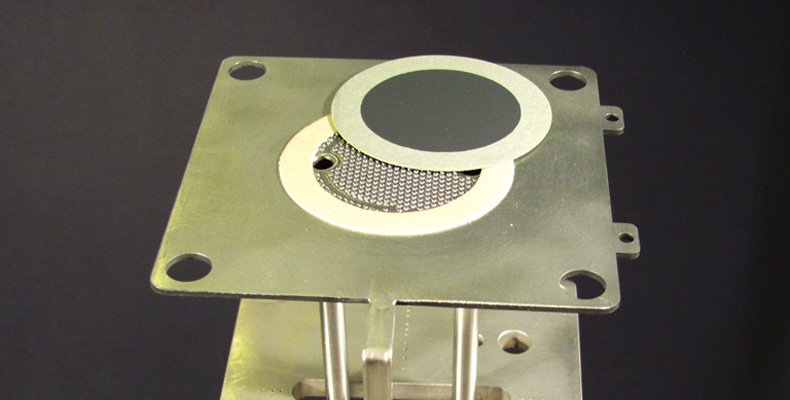

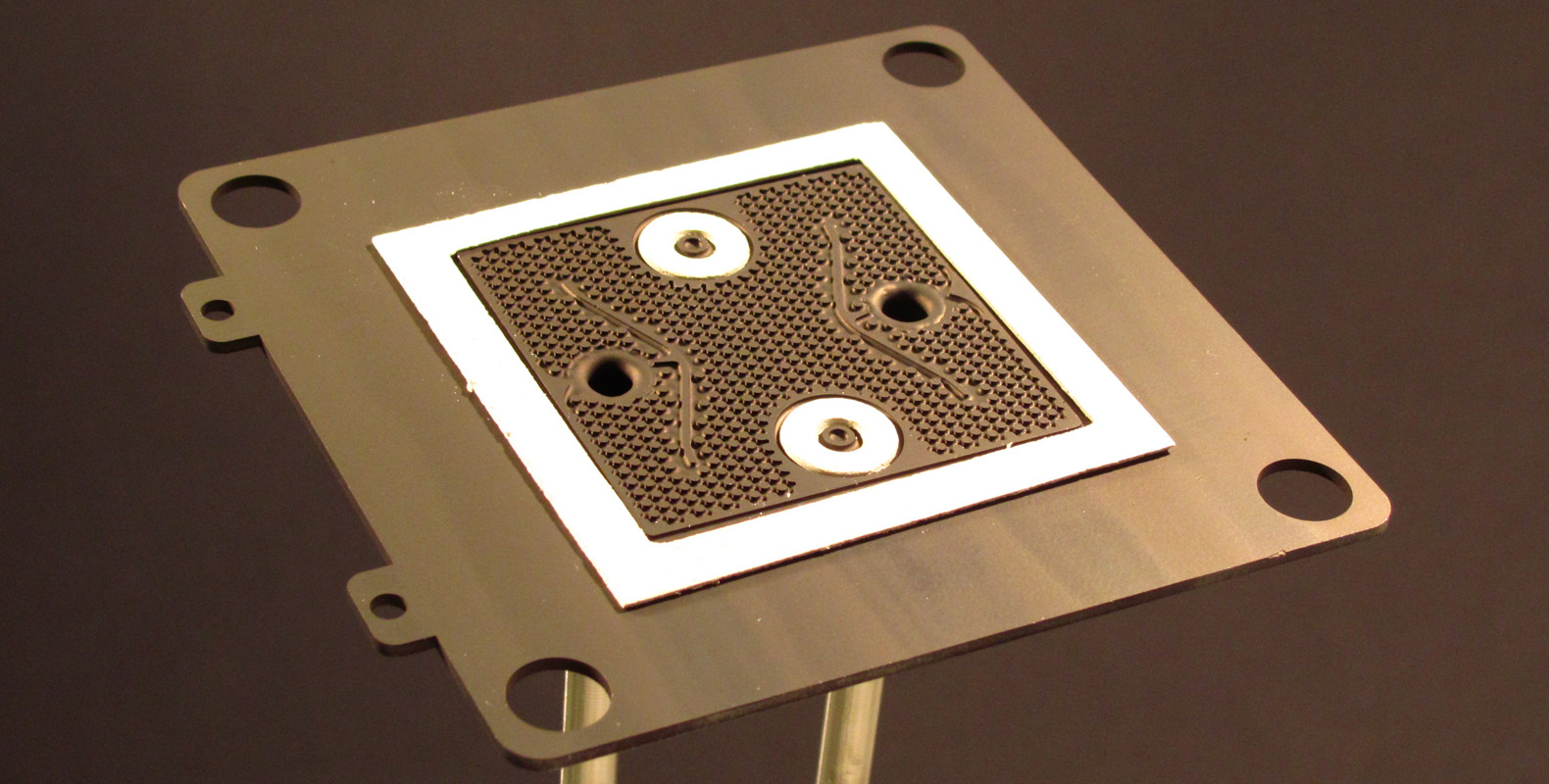

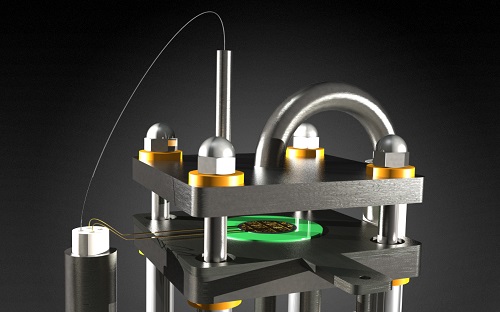

One of the 4 "baby" flange head with nickel fuel diffuser and thermocouple holder for optimal cell temperature control. Here a gold M-Grid™ is used on the air electrode for ideal test condition

One of the 4 "baby" flange head with nickel fuel diffuser and thermocouple holder for optimal cell temperature control. Here a gold M-Grid™ is used on the air electrode for ideal test condition

Sealed option & exhaust gas recovery: the cell (anode and / or cathode chamber) can be sealed with soft and deformable mica, gold ring or glass. Exhaust gas are recovered through pipes for analysis. It is particularly important during H2O, CO2 co-electrolysis in order to measure the amount of H2 and CO generated

Constant pressure load: 4 external calibrated springs for each of the 4 flanges ensure a constant and controlled pressure on the cell during the whole experiment. Pressure range from naught to 50 Kg can be chosen and imposed to the cell in our SOFC / SOEC Multi-Flanges™ test bench. For the Multi-Flanges™, as 4 cells have to be installed in a same run, the "quick compression spring" mechanism has been implemented. It allows to instantly close and compress the cells to a pre-defined pressure without the need of any spring length measurement.

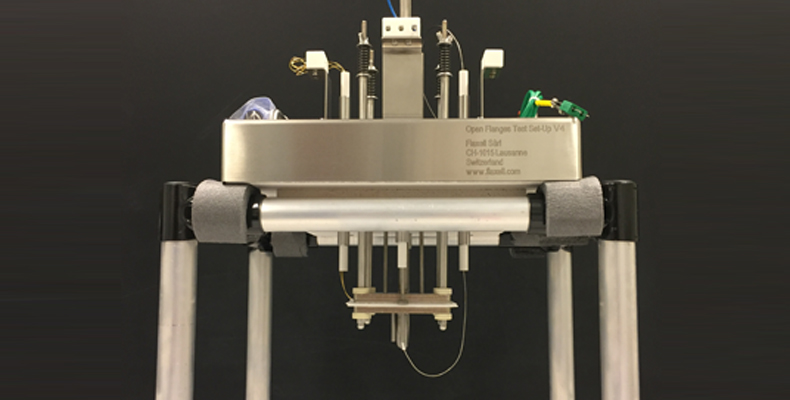

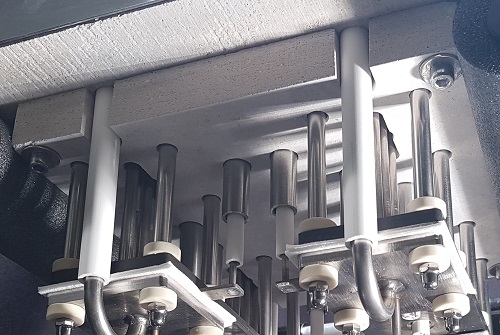

Bottom view of the SOFC / SOEC Multi-Flanges™ test stand in its furnace. It allows to run 4 cells simultaneously and independently.

Bottom view of the SOFC / SOEC Multi-Flanges™ test stand in its furnace. It allows to run 4 cells simultaneously and independently. Heating: the Set-Up comes with a robust German furnace that can be used for the sintering of all SOFC / SOEC components (electrodes, cell, powders etc.) up to 1320°C

Corrosion resistant & robust: flanges and tubes (air and fuel) made in Inconel 600 & 601. Our SOFC / SOEC button cell test fixture is built up to last for years

Technical training: the SOFC / SOEC Multi-Flanges™ button cell test fixture comes with a video manual with all detailed instructions sorted by experiment titles. A two days training is also offered in our lab. For years now, researchers in the field of solid oxide fuel cell & electrolyzer from universities around the world are meeting in our lab and exchanging scientific knowledge about fuel cell testing and fabrication. Training on customer's site is now also proposed

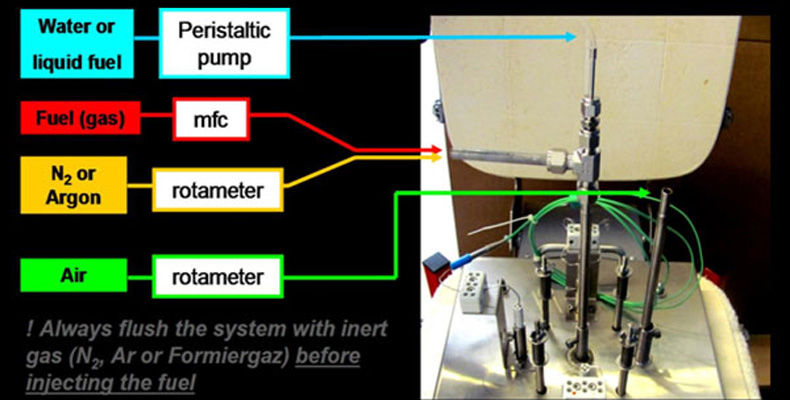

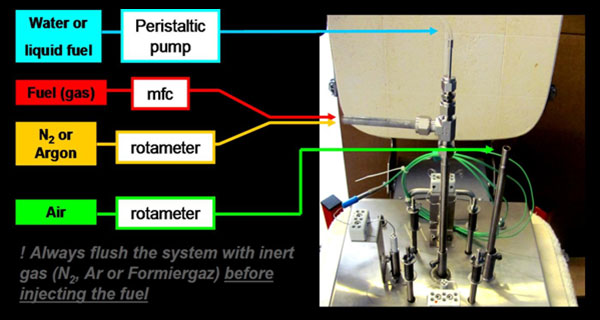

Integrated steamers for electrolysis and gas processing: Fiaxell has developed an integrated steamer for electrolysis and gas processing, the "Easy-Steam™" and the "CAT-PRO™". Thanks to a proprietary and optimized steamer design, a very constant steam flux flows on the cell, which is necessary to run impedance spectroscopy analysis during water electrolysis.

With this integrated steamer devices, the SOFC test station can instantly be transformed into a SOEC electrolyzer that produces hydrogen from the injected water.

Easy.Steam™ is an integrated steamer using the heat of the furnace to smoothly evaporate the injected water through a ceramic cartridge

Easy.Steam™ is an integrated steamer using the heat of the furnace to smoothly evaporate the injected water through a ceramic cartridge

When feeding the SOEC cell with H2O and CO2, co-electrolysis providing hydrogen and carbon monoxide will take place.

Liquid fuel (ethanol, methanol, ammonia, gazoline etc.) mixed with water can also be injected with the integrated steamer of our SOFC / SOEC test rig.

The optimized design of our integrated steamer, allows to load it with catalyst of choice and in-situ gas processing, as steam reforming (SR) or partial oxidation (POX) will take place before to reach the SOFC / SOEC cell. Furthermore, the probe for the gas temperature reading and the gas sampling capillary for GC analysis can be moved in the whole gas processing zone, giving the possibility of a step by step reaction study.

The Multi-Flanges™ SOFC / SOEC button cell test station is thus offering a complete turnkey solution for gas process analysis and co-electrolysis investigations.

Multi-Flanges™ preview: this CAD video presents the Multi-Flanges™ outside and inside its kiln.

At the beginning of the movie, one can see the new cable holders and front panel with up to 20 banana plugs.

They have been designed to sort the numerous electrical cables and maintained them at a certain distance from the hot zones of the furnace and and the Multi-Flanges™ stainless steel box surface.

On the Multi-Flanges™ box, 24 ceramic terminals can link the internal and external electrical connections.

The cable holders are also useful to hold on top of the box the 8 silicone tubes feeding air and fuel into the 4 cells.

Inside the furnace, one can observe the 4 flanges, each one with its wiring connection and thermocouple for cell temperature and potential reading.

Multi-Flanges™ versus Open-Flanges™

The table below summaries the characteristics given by the two setups and will help the SOFC/SOEC researchers to choose the most adapted device for their developments:

| Functionalities | Multi-Flanges™ (4-MF™) | Open-Flanges™ |

| Cell dimension | From Ø 5 up to Ø 40 mm and for square cell up to 30 X 30 mm | From Ø 5 up to Ø 80 mm and for rectangular cell up to 76 X 60 mm |

| Number of single cells per test | Up to 4 | 1 (see also stack below) |

| Easy-steam™ & CAT-PRO™ Integrated steamer for H2O /CO2 electrolysis and gas processing |

Yes | Yes |

| Sealing on fuel side Gas recovery on fuel side (for air side: only with spinel coated ferritic steel diffuser) |

Yes | Yes |

| Kiln | Squadro Q11 (hole in the bottom for long term kit) | Squadro Q11 (hole in the bottom for long term & short stack kit) |

| Long term testing kit Ceramic housing on air side to avoid any chromium poisoning during long term operation |

Yes | Yes |

| Ideal condition testing Nickel diffuser on fuel side and gold M_Grid™ on air side |

Yes | Yes |

|

Real condition testing |

Yes | Yes |

| Short stack | No | Yes |

| New functionalities | Multi-Flanges™ (4-MF™) | Open-Flanges™ |

| Cable holder Allows to sort and hold each cables and gas tubes away from the hot zone of the setup box and kiln surface |

Yes | Since June 2021 |

|

Large front panel |

Yes | Since January 2022 |

| Quick spring compression Allows to quickly compress the flanges at a pre-defined force without spring length measurement |

Yes | Only on request |

Fiaxell is the manufacturer and supplier of the SOFC / SOEC Multi-Flanges™ (4-MF™) button cell tester. The test fixture is highly flexible and allows a wide range of SOFC / SOEC type of experiments such as long term test in ideal conditions, co-electrolysis, gas processing, real and ideal conditions testing (see also test kit in the main menu)

Download the brochure:

Click on the picture to download the SOFC / SOEC button cell tester technical data sheet or click here to go to all Fiaxell prospectus