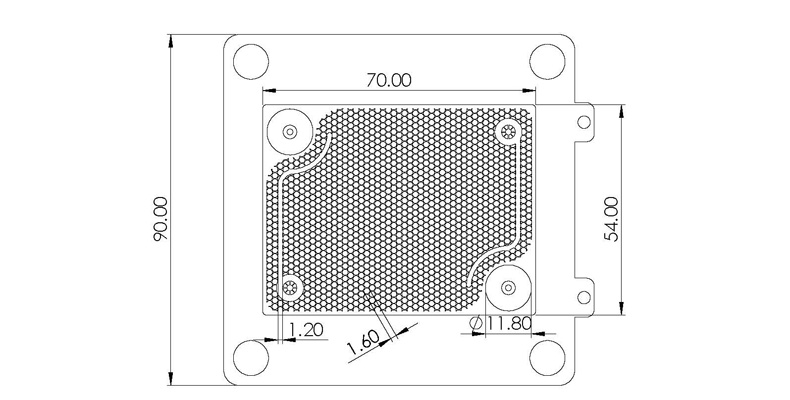

2R-Cell™

A robust and redox resistant cell

Why using a redox cell ?

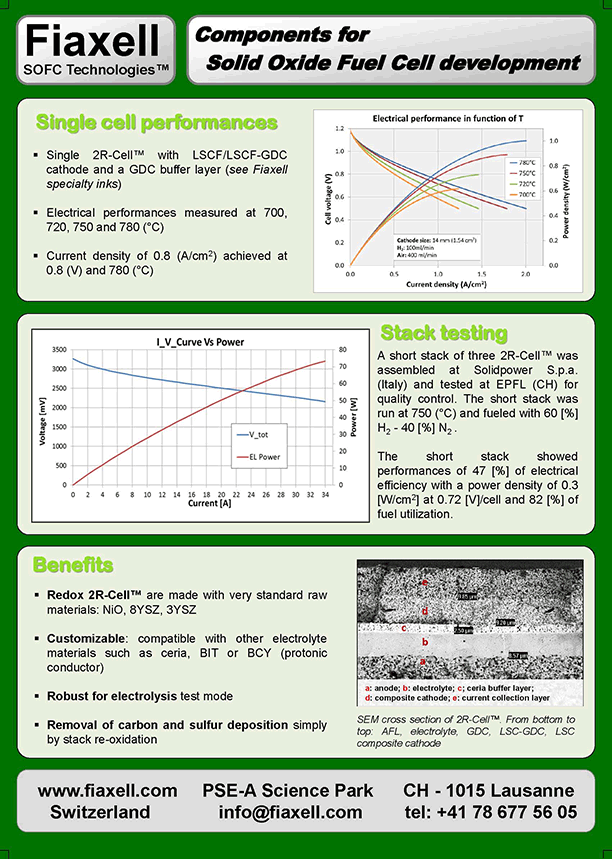

Standard anode supported cell (ASC) can deliver high power density in a wide range of temperature but are destroyed when re-oxidation occurs. The reason is the expansion of the anode support when the metallic nickel re-oxidizes, which causes micro-cracks in the electrolyte and anode support (see picture below).

Standard ASC cell are totally broken after only one reoxidation cycle (left). This originates from micro-cracks in the anode and electrolyte caused by the expansion of the anode substrate during reoxidation (right).

Standard ASC cell are totally broken after only one reoxidation cycle (left). This originates from micro-cracks in the anode and electrolyte caused by the expansion of the anode substrate during reoxidation (right).

It induces fuel leaks through the electrolyte and causes a quick degradation of the performances and destruction of the anode supported cell. This happens, for instance when fuel supply inappropriately stops. Cell peripheral re-oxidation is another well known figure where failures are initiated. In all cases, when re-oxidation starts, the stack quickly undergoes a fatal destruction and the SOFC system definitely falls down.

2R-Cell™: the anode supported cell that withstands redox cycles

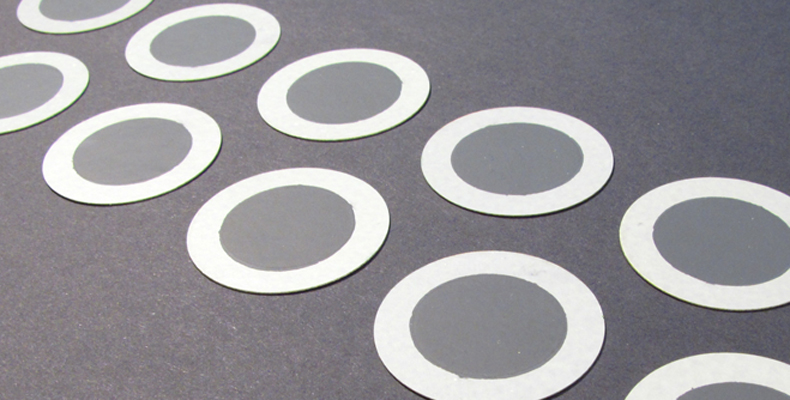

Through a proprietary technique, Fiaxell has developed a robust, reliable and redox resistant anode supported (ASC) cell. 2R-Cell™ are made with very standard raw materials as NiO, 8YSZ, 3YSZ. The redox resistance is obtained thanks to a proper organization of the microstructure of the two different phases (NiO and 3YSZ) in the anode support. It allows the metallic nickel to re-oxidised without expansion of the anode substrate as it is the case in the standard anode supported cell (see picture above). Fiaxell is the manufacturer and supplier of the redox anode supported cell (ASC).

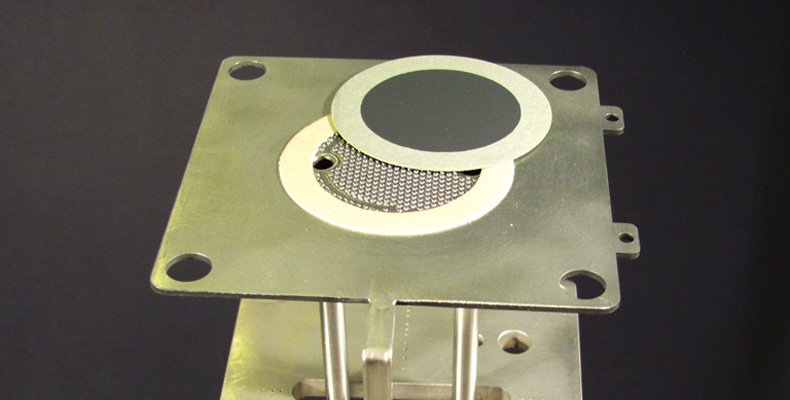

2R-Cell™ of 80 X 80 mm that underwent 10 full redox cycles and 2 thermo-cycles without any failure or mechanical properties loss.

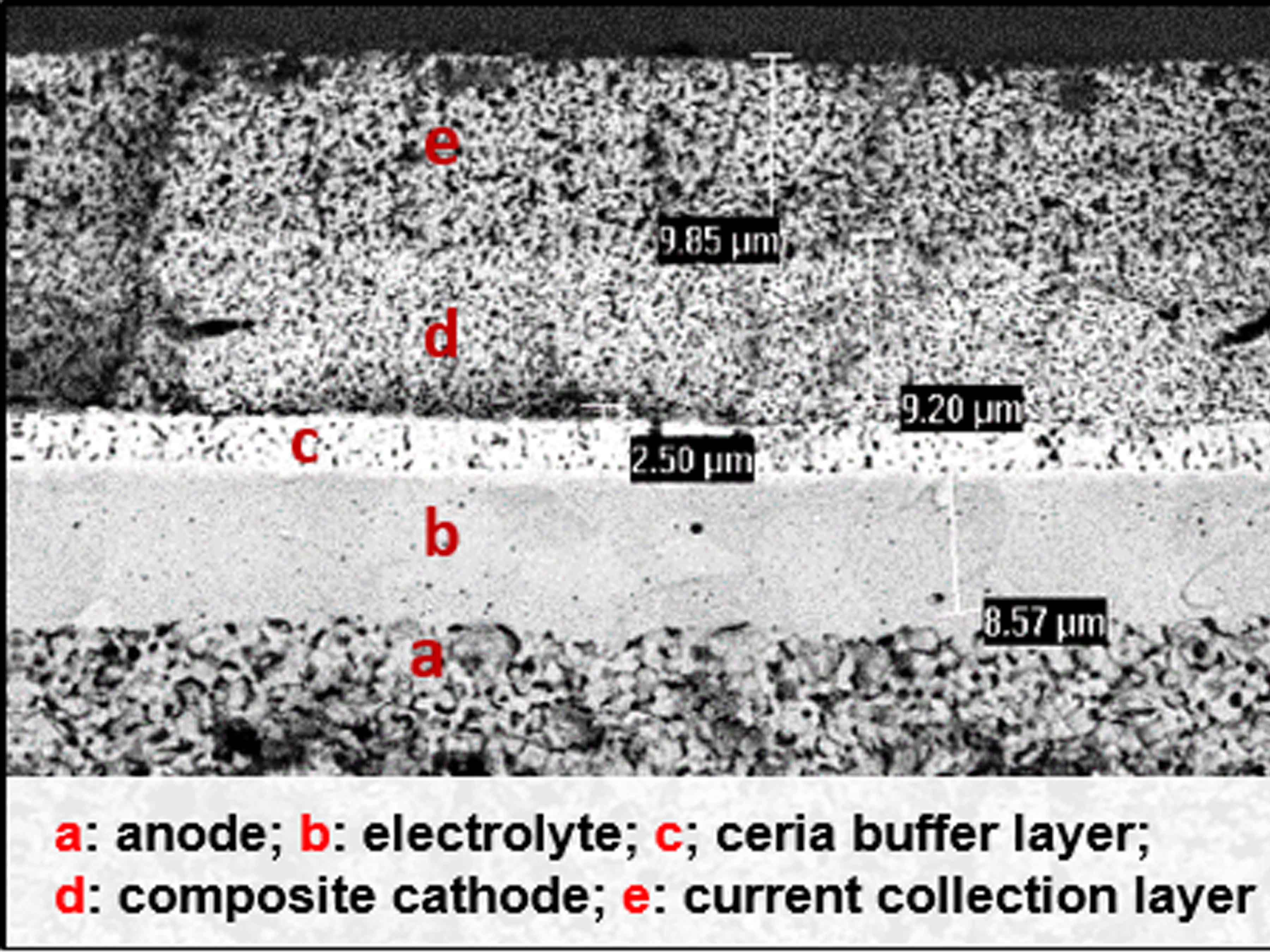

2R-Cell™ of 80 X 80 mm that underwent 10 full redox cycles and 2 thermo-cycles without any failure or mechanical properties loss.  SEM cross section of a 2R-Cell™ after few redox cycles without any visible crack in the structure

SEM cross section of a 2R-Cell™ after few redox cycles without any visible crack in the structureThe mechanical properties, measured with ball-on-ring testing method at University of Trento (Italy), showed no change before and after 10 redox cycles with a maximal bending strength of 180±10 Mpa and a Weibull modulus of 9, which indicates a reliable ceramic.

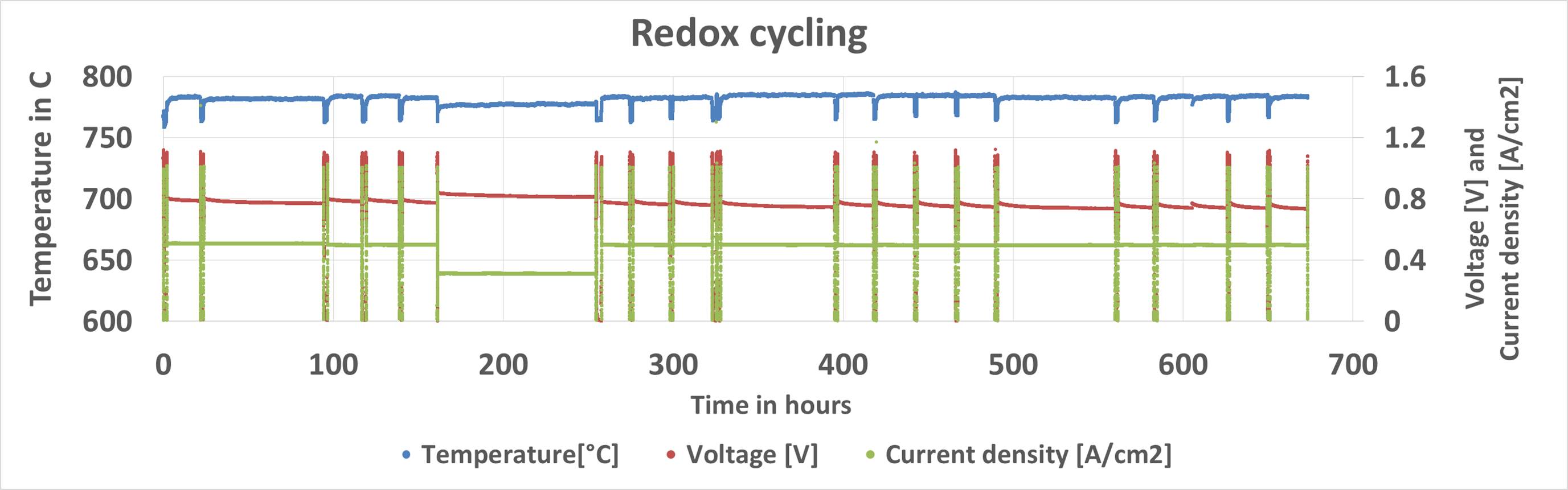

The graph (below) shows a test carried out at EPFL (Swiss Institute of Technology, Switzerland) in which 20 redox cycles were performed without any mechanical damage of the 2R-Cell™.

Temperature (blue), voltage (red) and current density (green) of a 2R-Cell™ subjected to 20 redox cycles without any mechanical property change. Only a small increase of ASR of about 0.5%/cycle could be observed

Temperature (blue), voltage (red) and current density (green) of a 2R-Cell™ subjected to 20 redox cycles without any mechanical property change. Only a small increase of ASR of about 0.5%/cycle could be observed

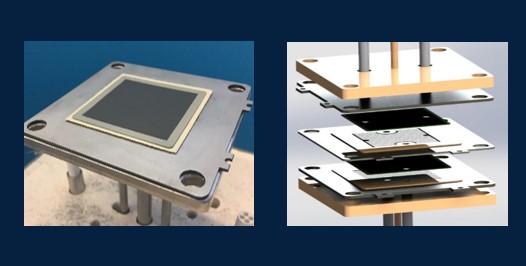

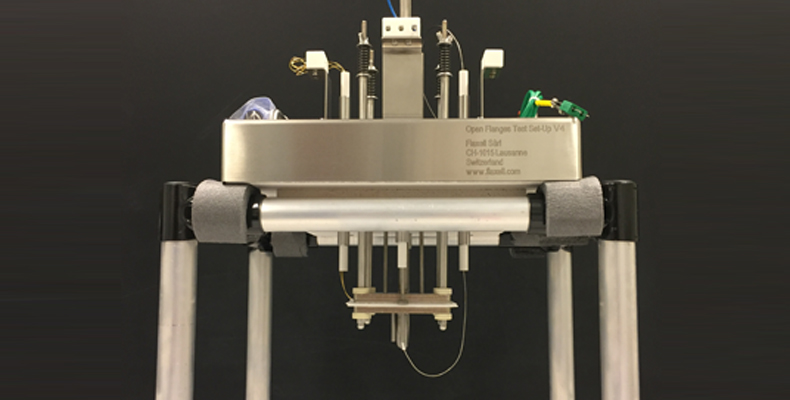

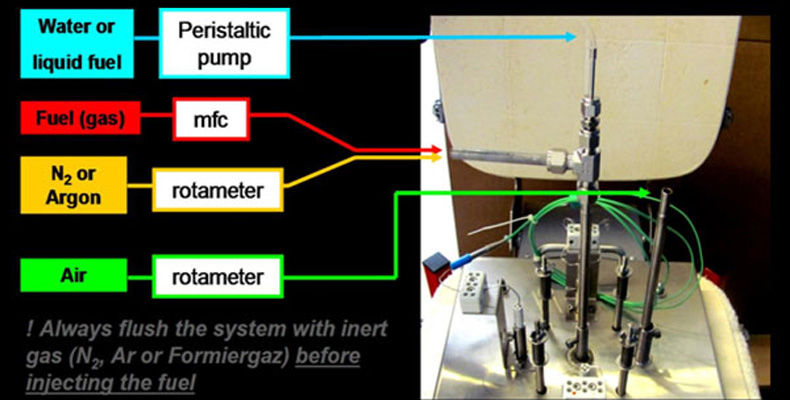

Single cell performances

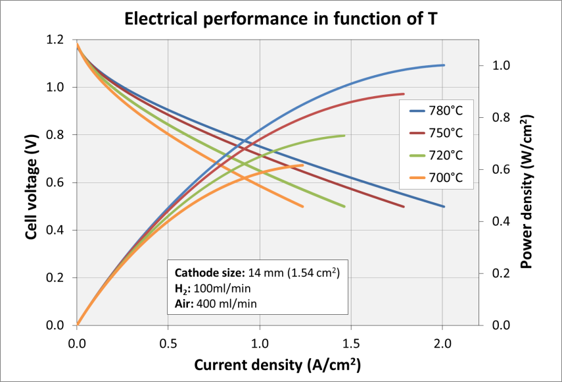

2R-Cell™ equipped with LSCF/LSCF-GDC cathode and a GDC buffer layer (see Fiaxell specialty inks) have been tested as single cells in the Open Flanges Set-Up at different temperatures and flow rates. The results are presented in the two graphs below.

Electrical performances of 2R-Cell™ tested between 700 and 780 °C. At the highest temperature, 1 mW/cm2 is achieved

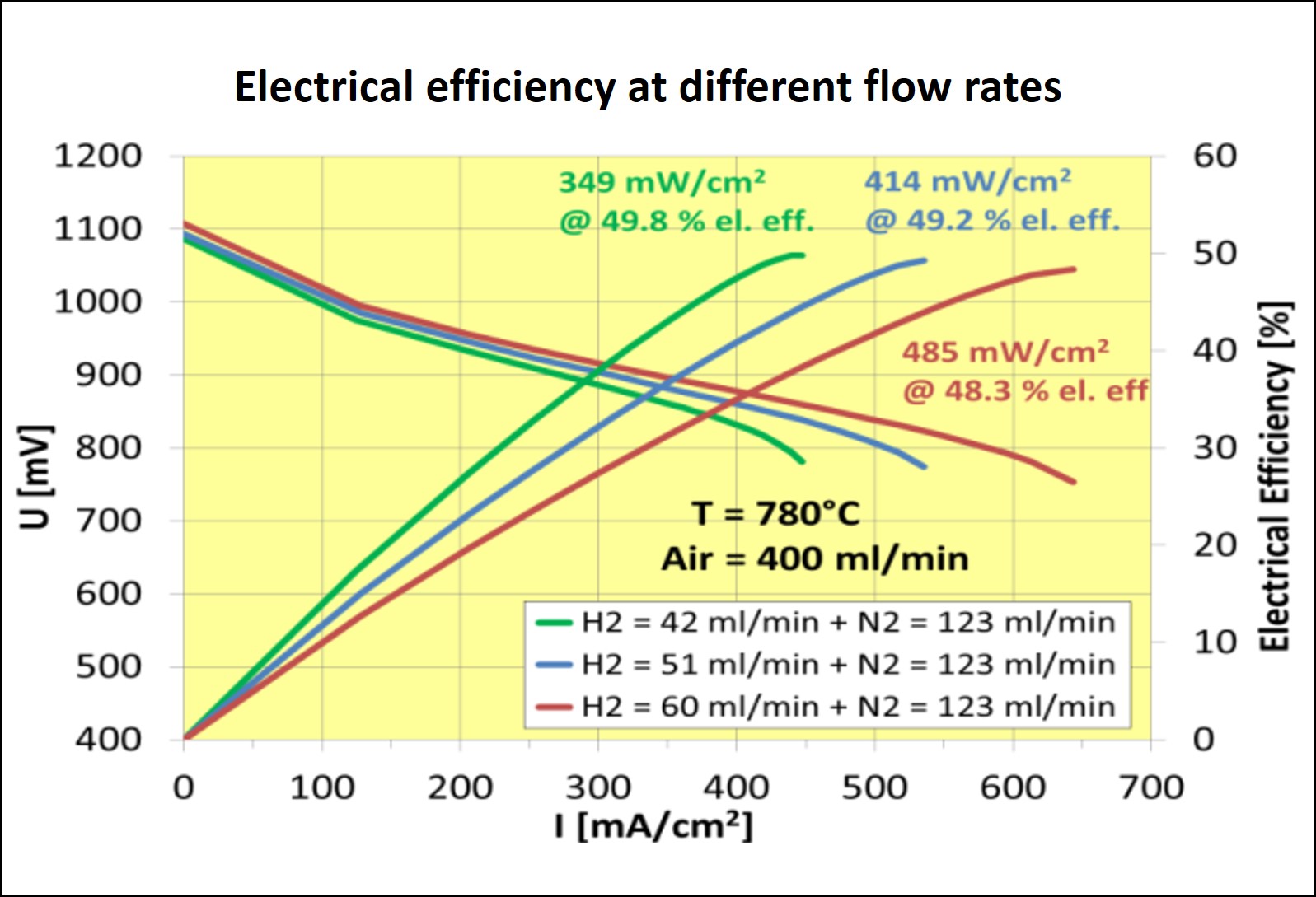

Electrical performances of 2R-Cell™ tested between 700 and 780 °C. At the highest temperature, 1 mW/cm2 is achieved Electrical efficiency of 2R-Cell™ tested under dry hydrogen. For the three different flow rates, near 50 % of efficiency could be reached

Electrical efficiency of 2R-Cell™ tested under dry hydrogen. For the three different flow rates, near 50 % of efficiency could be reached Stack testing

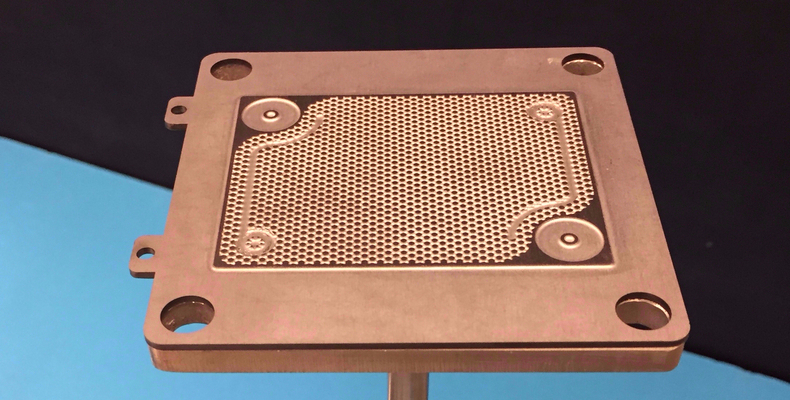

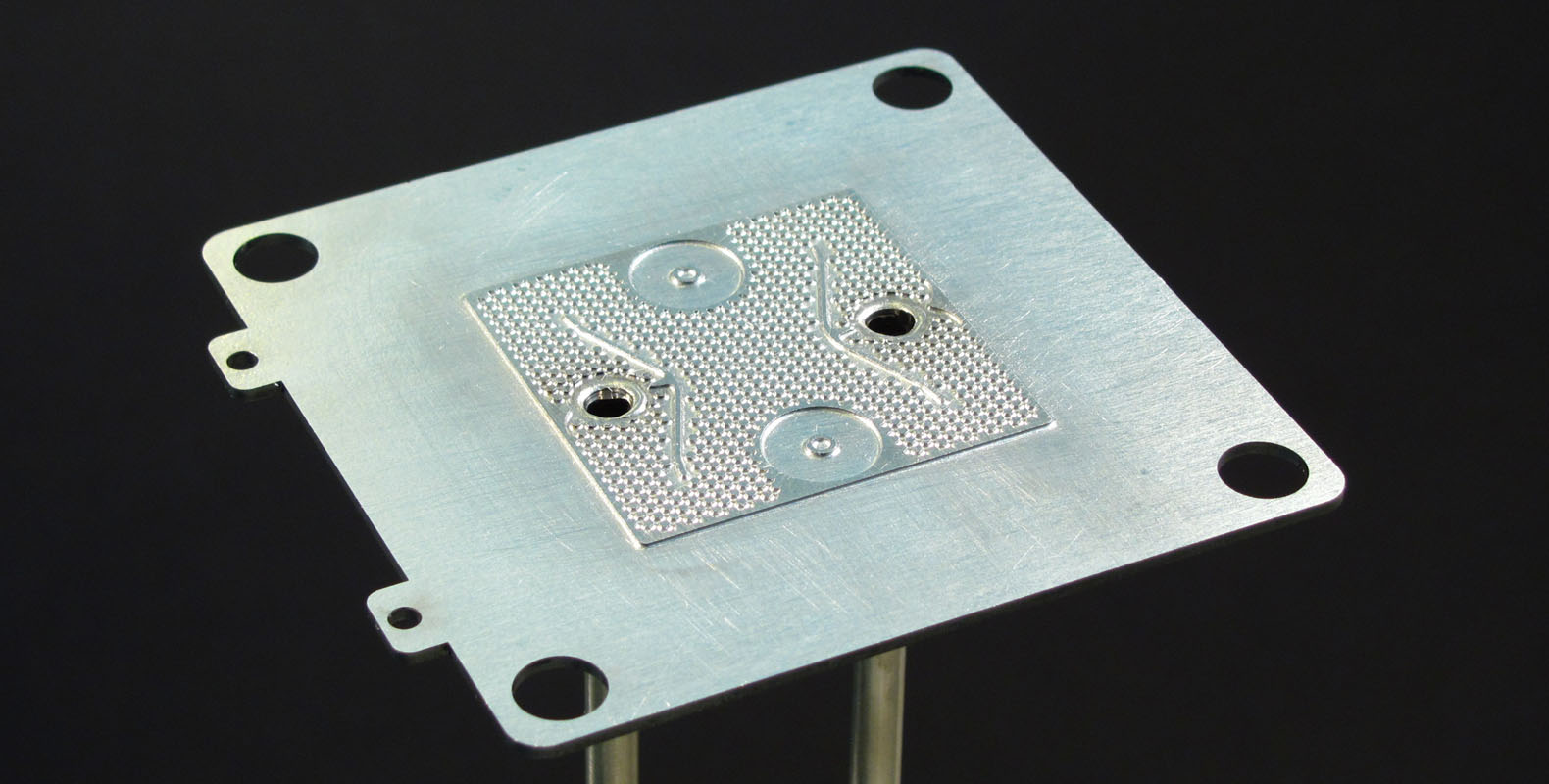

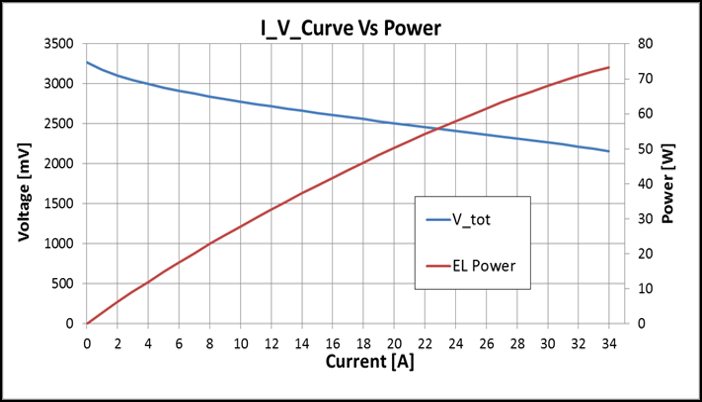

A short stack of three 2R-Cell™ was assembled at Solidpower S.p.a. (Italy) and tested at EPFL (Swiss Institute of Technology, Switzerland) for quality control. The short stack was run at 750 (°C) and fueled with 60 [%] H2 - 40 [%] N2 . The 2R-Cell™ in the short stack showed performances of 47 [%] of electrical efficiency with a power density of 0.3 [W/cm2] at 0.72 [V]/cell and 82 [%] of fuel utilization.

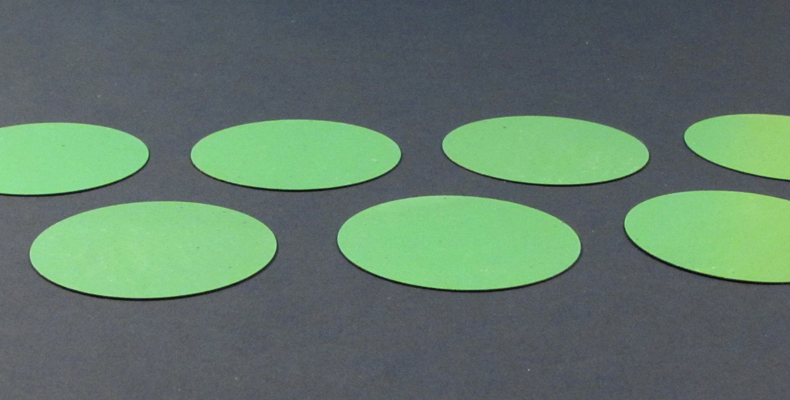

Large 2R-Cell™ used to equip the three cell stack

Large 2R-Cell™ used to equip the three cell stack  IV curve and total power of the three 2R-Cell™

IV curve and total power of the three 2R-Cell™Benefits of using 2R-Cell™

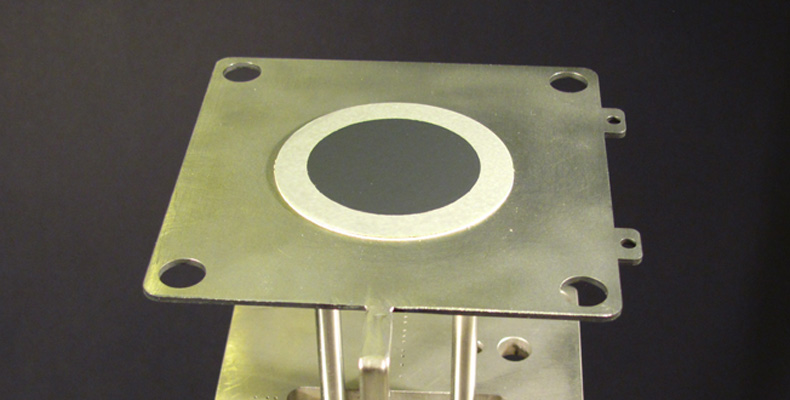

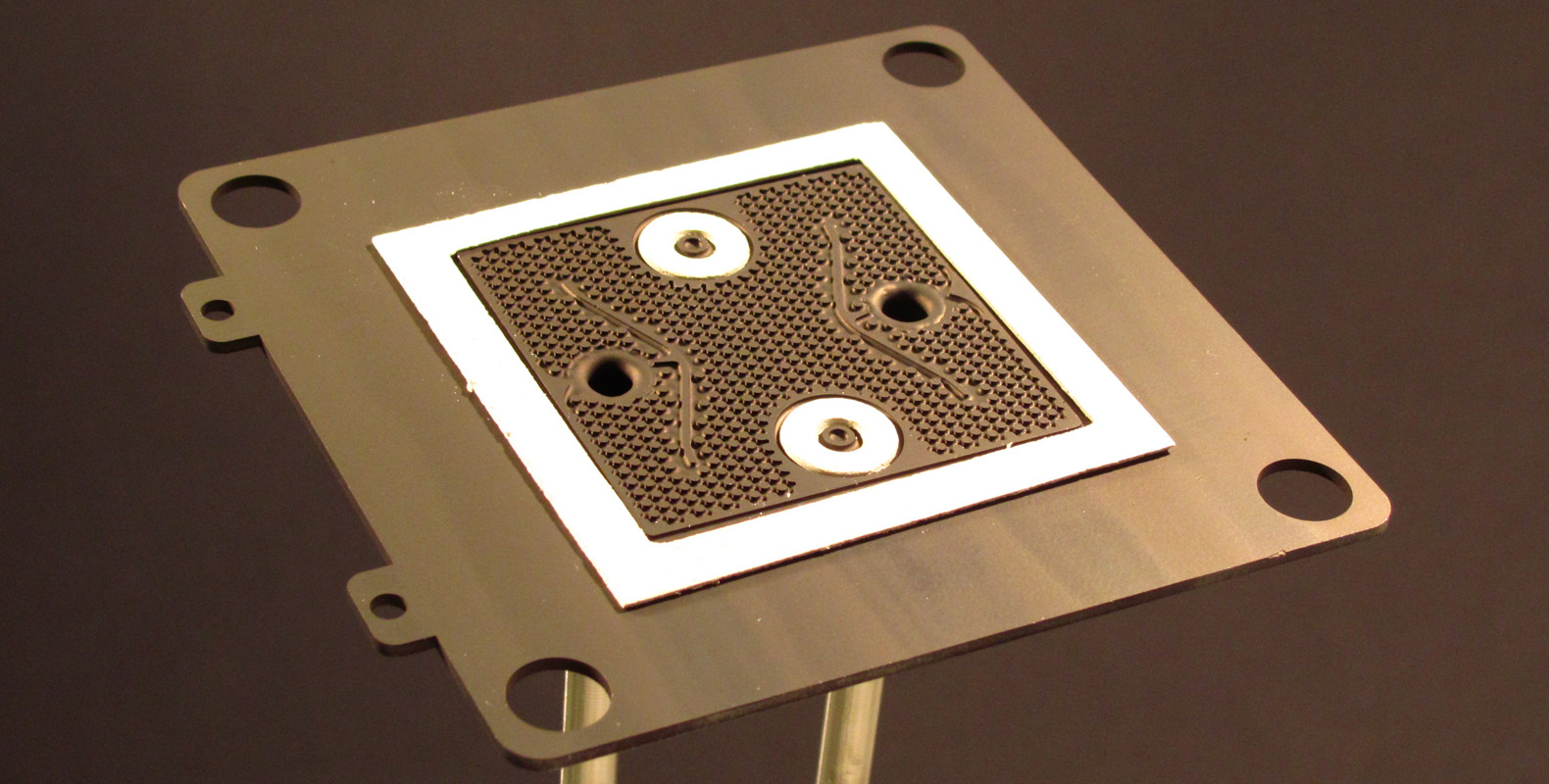

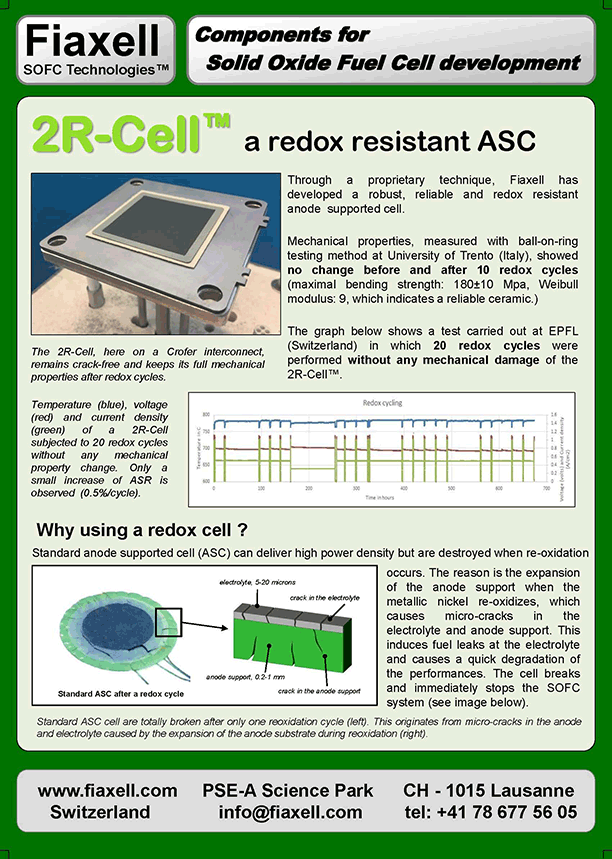

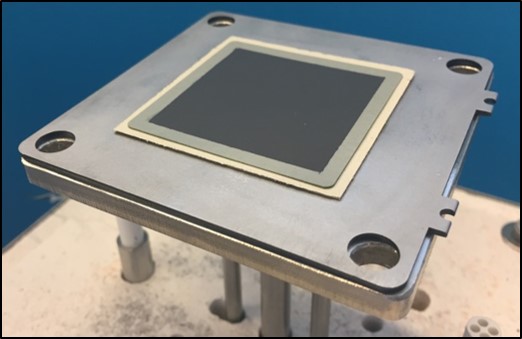

The 2R-Cell™, here on a Crofer interconnect, remains crack-free and keeps its full mechanical properties after redox cyclesVery standard raw materials: NiO, 8YSZ, 3YSZ are used to fabricate the redox 2R-Cell™

The 2R-Cell™, here on a Crofer interconnect, remains crack-free and keeps its full mechanical properties after redox cyclesVery standard raw materials: NiO, 8YSZ, 3YSZ are used to fabricate the redox 2R-Cell™- Customizable: compatible with other electrolyte materials such as doped ceria (GDC, SDC) or protonic conductor (BCY, BCZY)

- Robust for electrolysis, pure steam (without H2) can be directly injected on the 2R-Cell without any risk of cell destruction as it is the case with standard ASC

- Stack operation at high fuel utilization without risk of failures in the fuel underfed zones of the cell

- On/off operations for portable devices can be operated directly in closing the gas bottle

- Removal of carbon and sulfur deposition simply by quick stack re-oxidation that will volatilize the impurities into SO2 and CO2

2R-Cell™ have been developed to bring one more security factor to SOFC system. It is a protection against fuel supply failure and cell peripheral re-oxidation that can lead to fatal stack destruction

Download the brochure:

Click on the picture to download the brochure or click here to go to all Fiaxell brochures