Fiaxell technical brochures (all data sheet)

For high temperature fuel cell (SOFC) & electrolyzer (SOEC) testing equipment and ceramic manufacturing

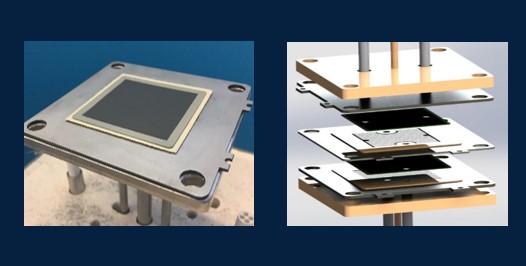

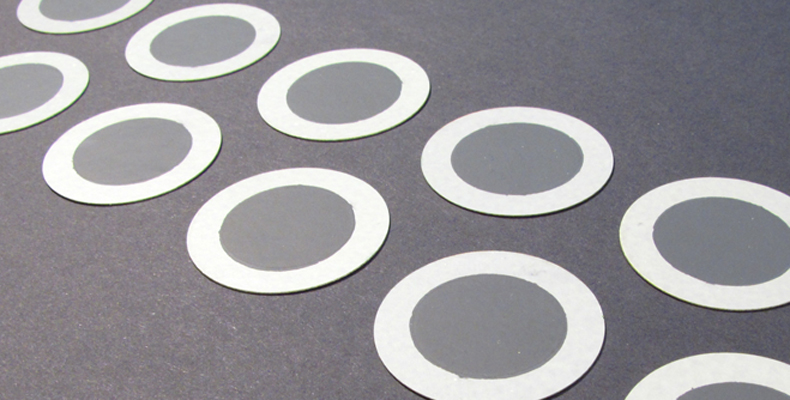

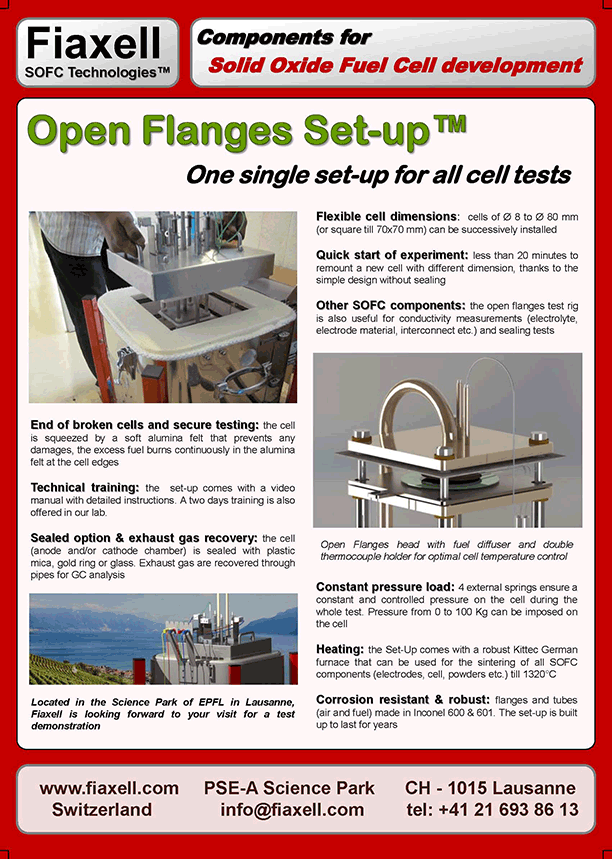

Our dedicated SOFC / SOEC fixture is able to test small button cells from 8 mm up to 80 mm in diameter or 10 X 10 up to 60 X 76 mm for rectangular cell. Gasket made of soft mica, glass or gold allows for gas recovery needed in case of water and carbon dioxide co-electrolysis (H2 / H2O, CO / CO2) gas exhaust analysis. High fuel utilisation can be achieved and up to 50 % of electrical efficiency is achieved with hydrogen as fuel (Fiaxell is manufacturer & supplier for the SOFC / SOEC button cell test fixture and all the kit:short stack system, long term test and tubular)

Our dedicated SOFC / SOEC fixture is able to test small button cells from 8 mm up to 80 mm in diameter or 10 X 10 up to 60 X 76 mm for rectangular cell. Gasket made of soft mica, glass or gold allows for gas recovery needed in case of water and carbon dioxide co-electrolysis (H2 / H2O, CO / CO2) gas exhaust analysis. High fuel utilisation can be achieved and up to 50 % of electrical efficiency is achieved with hydrogen as fuel (Fiaxell is manufacturer & supplier for the SOFC / SOEC button cell test fixture and all the kit:short stack system, long term test and tubular)

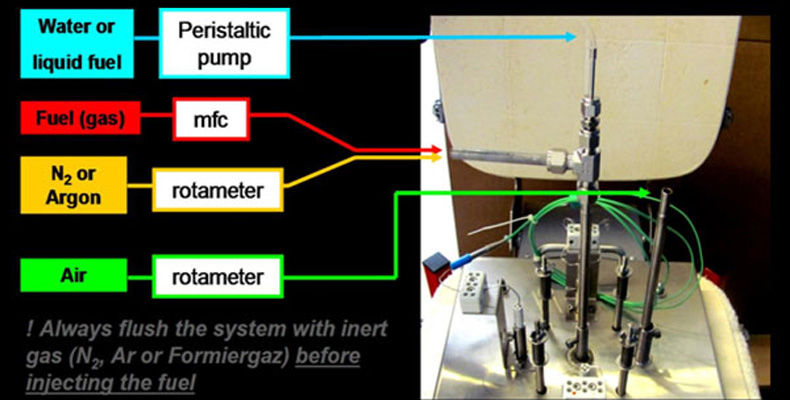

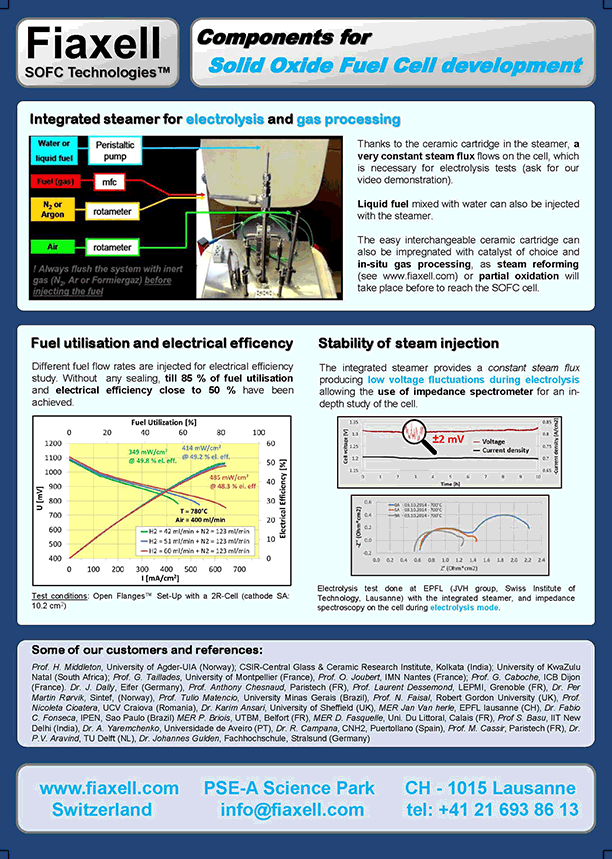

Thanks to an integrated steamer, our SOFC test station can immediately switch to electrolysis mode (SOEC) and transform, as an electrolyzer, water into hydrogen and CO2 into CO. In this case, the system acts as a reversible solid oxide fuel cell. Gas processing as steam reforming (CH4 + H2O→ H2 + CO) can also easily be carried on with this steam injector. Temperature reading and gas sampling for analysis can be followed in the whole gas processing zone

Thanks to an integrated steamer, our SOFC test station can immediately switch to electrolysis mode (SOEC) and transform, as an electrolyzer, water into hydrogen and CO2 into CO. In this case, the system acts as a reversible solid oxide fuel cell. Gas processing as steam reforming (CH4 + H2O→ H2 + CO) can also easily be carried on with this steam injector. Temperature reading and gas sampling for analysis can be followed in the whole gas processing zone

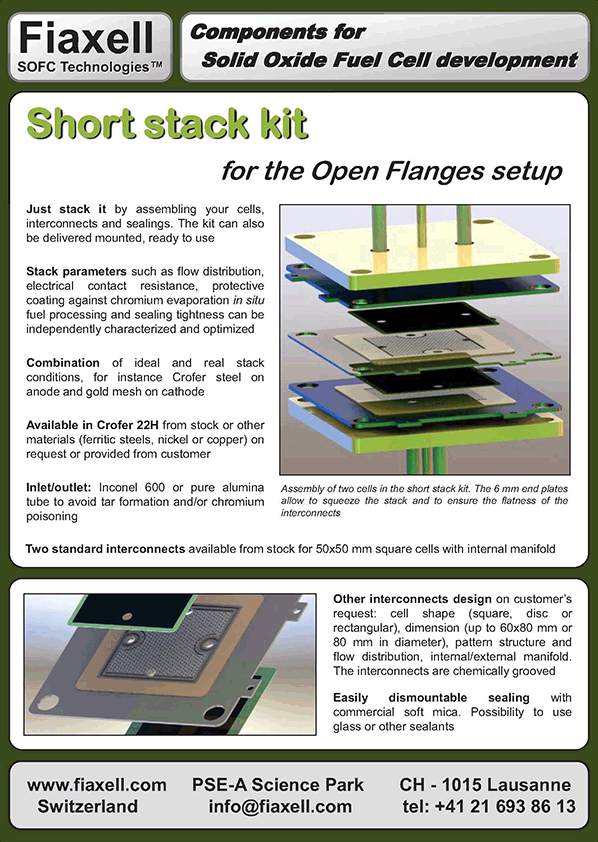

Without any change, a short stack can be installed on the SOFC / SOEC test system. Ideal for 50 X 50 mm square cells (stack for 100 X 100 mm cell is in preparartion), it allows to study all the stack parameters as the sealing (gasket), the protective layer on the interconnect against chromium evaporation, the fuel & air pressure drop and the temperature homogeneity. Ideal or real test conditions can be chosen on each side (air & fuel)

Without any change, a short stack can be installed on the SOFC / SOEC test system. Ideal for 50 X 50 mm square cells (stack for 100 X 100 mm cell is in preparartion), it allows to study all the stack parameters as the sealing (gasket), the protective layer on the interconnect against chromium evaporation, the fuel & air pressure drop and the temperature homogeneity. Ideal or real test conditions can be chosen on each side (air & fuel)

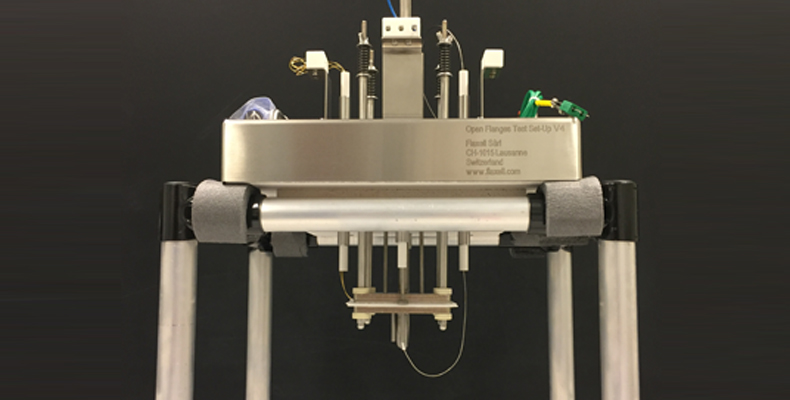

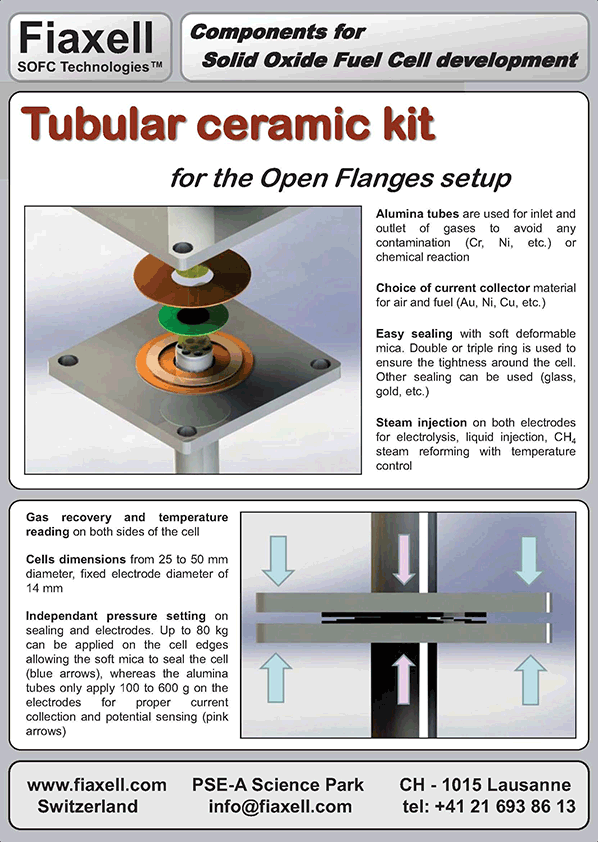

The tubular SOFC / SOEC button cell test rig uses pure alumina tube for inlet & exhaust gases (H2O, H2, CO2, CO, NH3 etc.) in order to avoid any contamination of chromium (Cr), nikel (Ni) or silicon (Si). It is an ideal test bench for protonic cells (BCY, BCZY) for hydrogen and CO2 co-electrolysis. The fixture allows also to test molten carbonate fuel cell (MCFC) and thermo-electric ceramics

The tubular SOFC / SOEC button cell test rig uses pure alumina tube for inlet & exhaust gases (H2O, H2, CO2, CO, NH3 etc.) in order to avoid any contamination of chromium (Cr), nikel (Ni) or silicon (Si). It is an ideal test bench for protonic cells (BCY, BCZY) for hydrogen and CO2 co-electrolysis. The fixture allows also to test molten carbonate fuel cell (MCFC) and thermo-electric ceramics

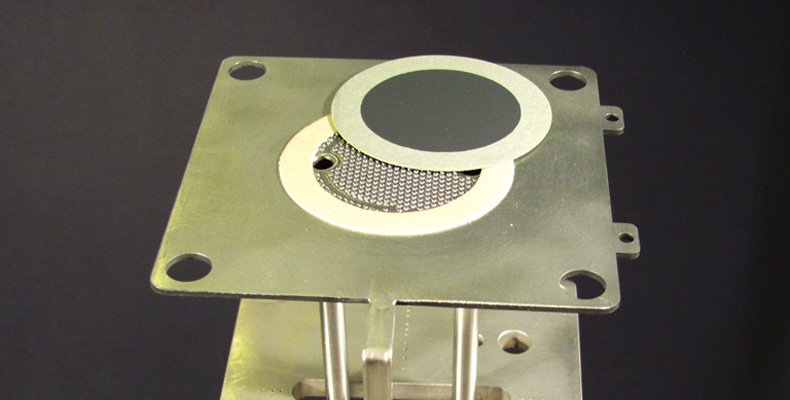

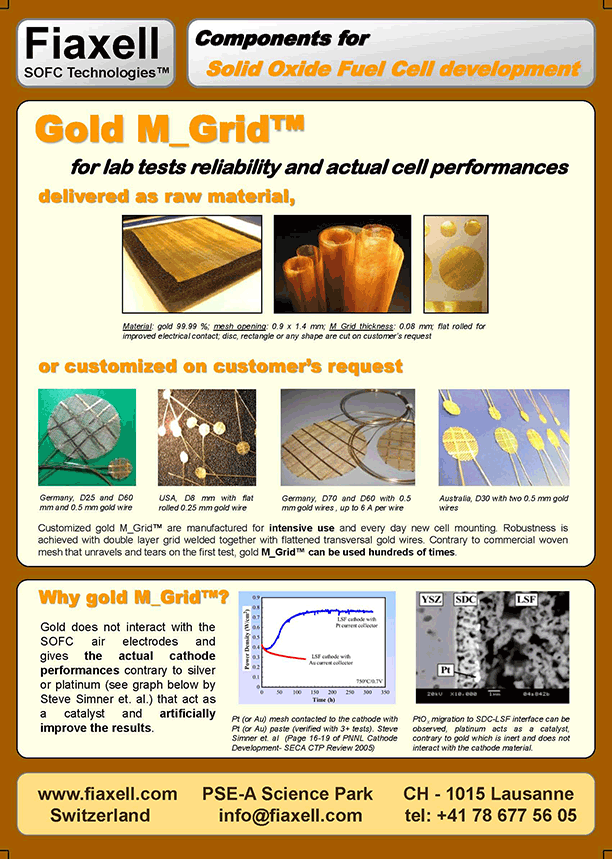

Our robust Au M_Grid™ are made with gold of 99.99 % purity. They are very robust and manufactured for intensive use. Gold does not interact with the SOFC / SOEC air electrodes and gives the actual cathode performances contrary to silver or platinum that act as a catalyst and artificially improve the results. Our gold meshes are delivered as raw material or customized (re-inforced disc or 3D-structure) on customer request (Fiaxell is for gold mesh manufacturer & supplier)

Our robust Au M_Grid™ are made with gold of 99.99 % purity. They are very robust and manufactured for intensive use. Gold does not interact with the SOFC / SOEC air electrodes and gives the actual cathode performances contrary to silver or platinum that act as a catalyst and artificially improve the results. Our gold meshes are delivered as raw material or customized (re-inforced disc or 3D-structure) on customer request (Fiaxell is for gold mesh manufacturer & supplier)

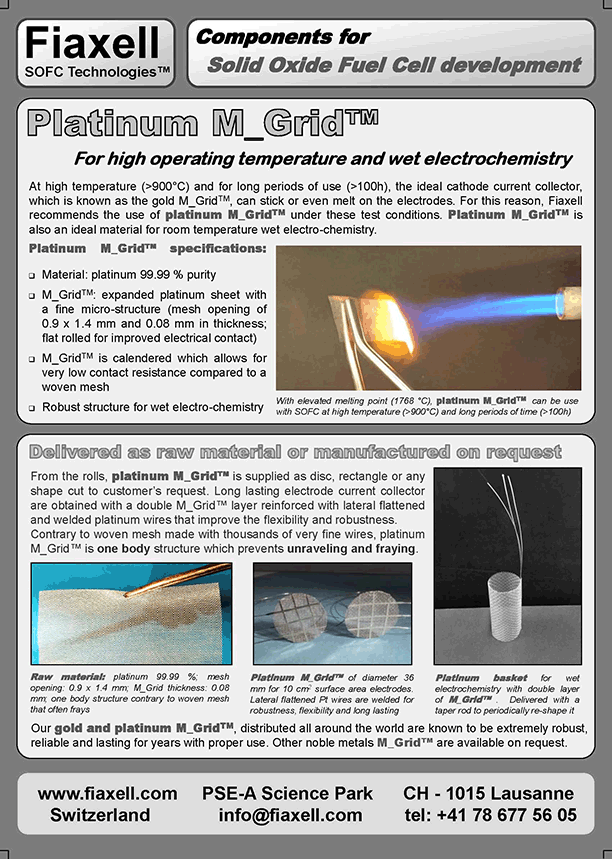

Our robust Pt M_Grid™ are made with 99.95 % platinum purity. Platinum gauze and meshes find their use at high temperature (>850°C) where gold can stick or even melt on electrodes. In wet electro-chemistry (electro-deposition, corrosion, redox-flow batteries), Pt M_Grid™ are perfect for counter electrode to drive high current density. Delivered as raw material or customized (basket, discs, etc.) on customer request (Fiaxell is for platinum (Pt) mesh manufacturer & supplier)

Our robust Pt M_Grid™ are made with 99.95 % platinum purity. Platinum gauze and meshes find their use at high temperature (>850°C) where gold can stick or even melt on electrodes. In wet electro-chemistry (electro-deposition, corrosion, redox-flow batteries), Pt M_Grid™ are perfect for counter electrode to drive high current density. Delivered as raw material or customized (basket, discs, etc.) on customer request (Fiaxell is for platinum (Pt) mesh manufacturer & supplier)

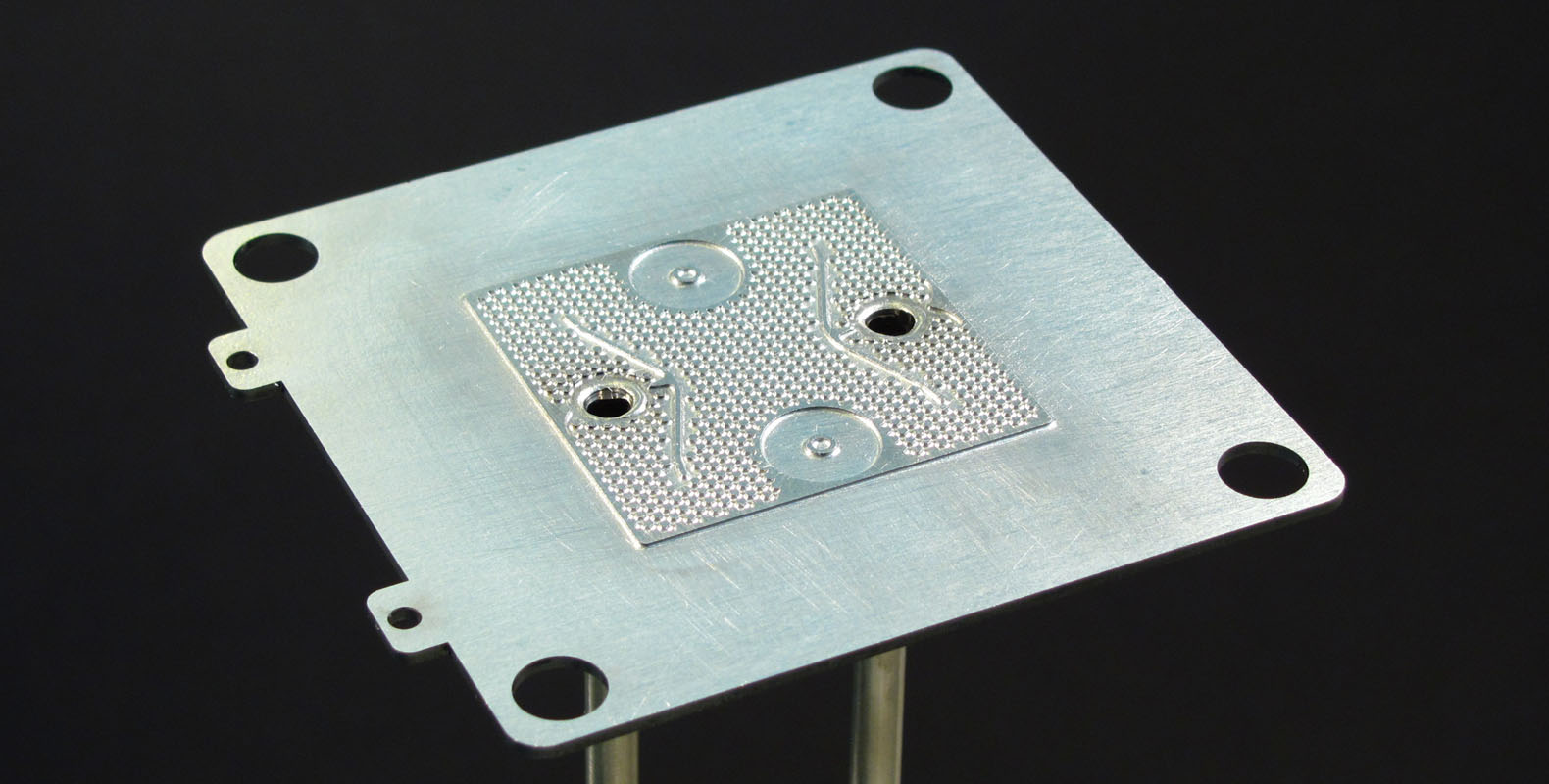

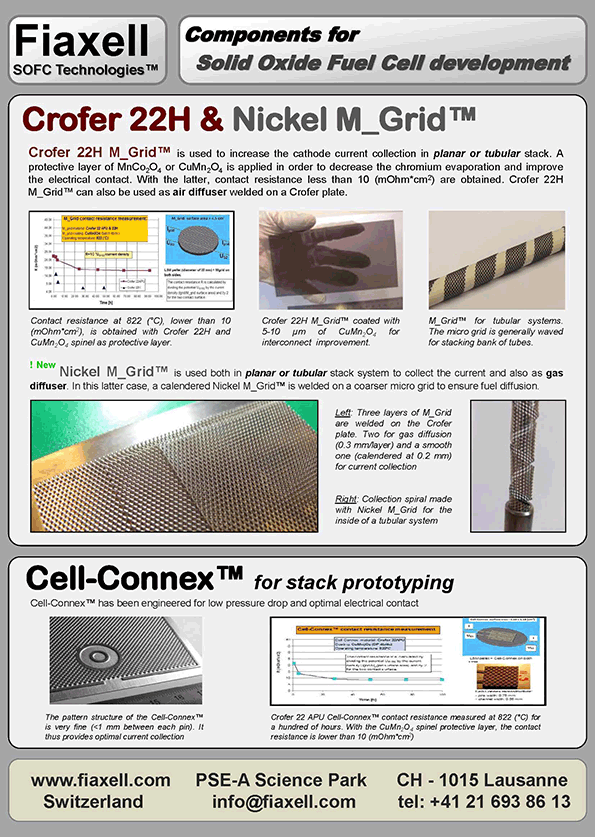

Crofer 22APU / 22H M_Grid™ have been designed to improve the cathode current collection in planar or tubular SOFC / SOEC stack. With a small mesh opening of 1.4 X 0.9 mm and a calendaring process to increase the contact surface area, they present very low electrical resistance between interconnects and cells. On air side, CuMn2O4 spinel protective layer is applied to prevent chromium poisoning and keep low contact resistance (Fiaxell is for Crofer mesh manufacturer & supplier)

Crofer 22APU / 22H M_Grid™ have been designed to improve the cathode current collection in planar or tubular SOFC / SOEC stack. With a small mesh opening of 1.4 X 0.9 mm and a calendaring process to increase the contact surface area, they present very low electrical resistance between interconnects and cells. On air side, CuMn2O4 spinel protective layer is applied to prevent chromium poisoning and keep low contact resistance (Fiaxell is for Crofer mesh manufacturer & supplier)

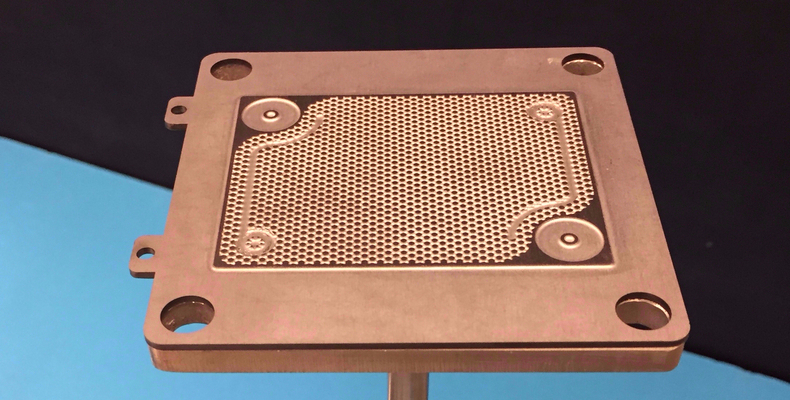

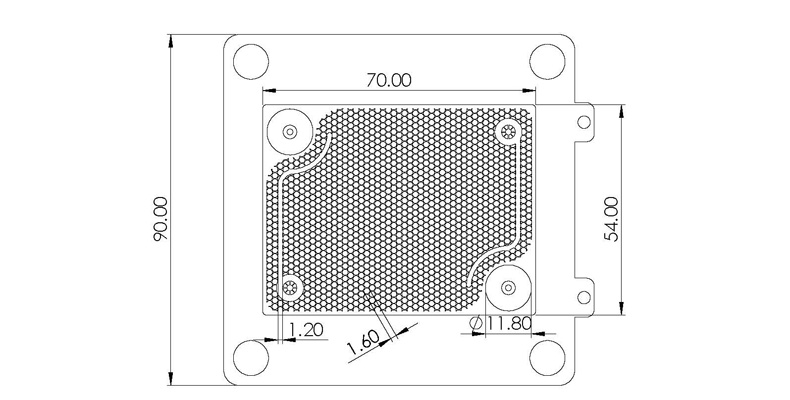

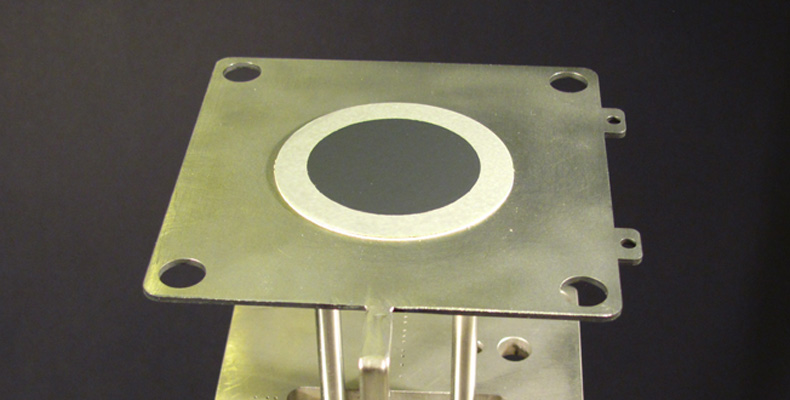

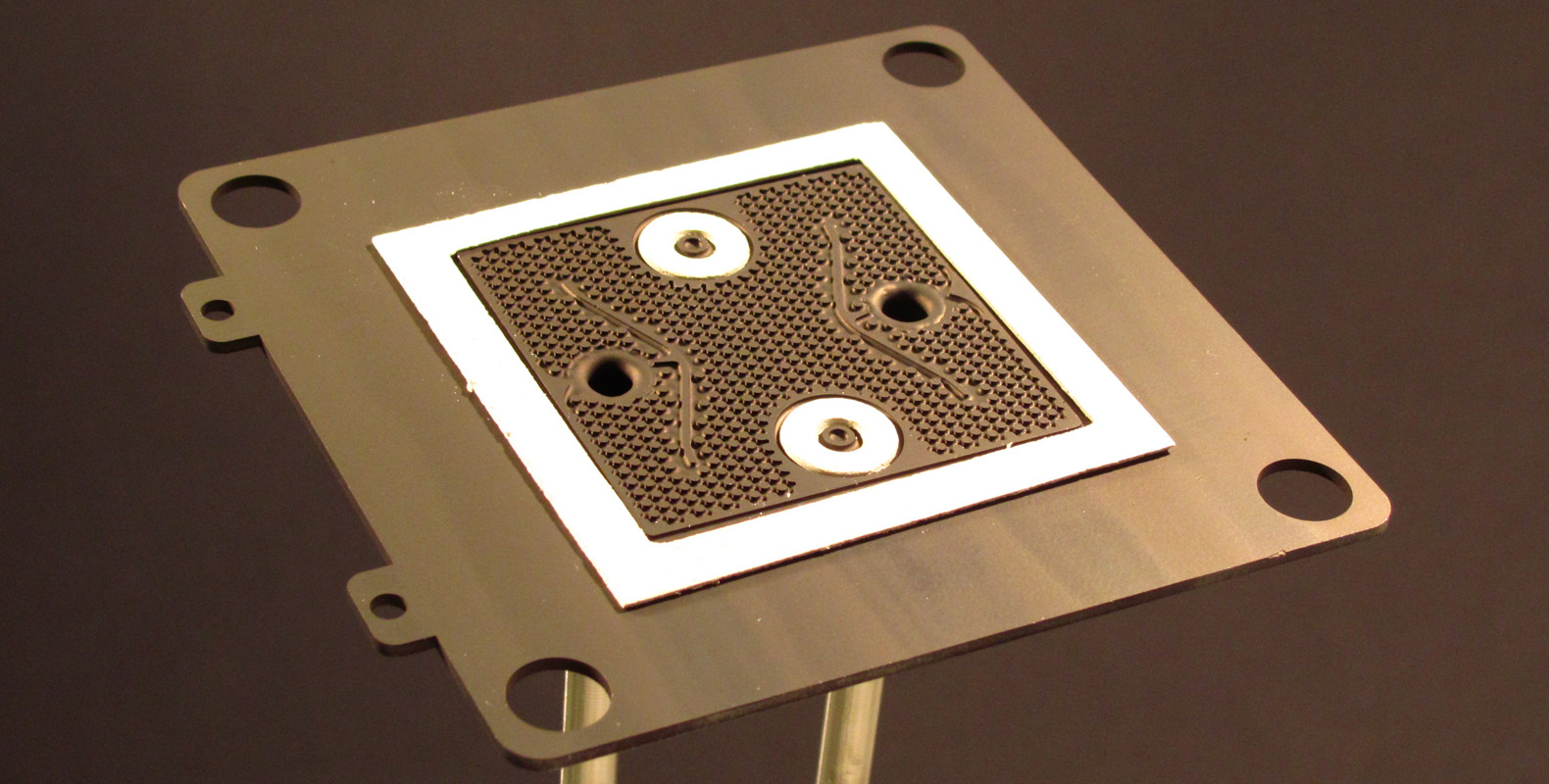

The Cell-Connex™ fuel cell interconnects are made of Crofer 22APU / 22H or other SOFC / SOEC dedicated ferritic steel (K41X, K44X, etc.). As they are grooved with a chemical milling process, any fine micro-structure and pattern design can be manufactured. Cell-Connex™ are ideal for stack prototyping. They are delivered with/out protective layer (NiO, MnCo2O4 or CuMn2O4 ) to avoid chromium evaporation and electrode poisoning (Fiaxell is for SOFC / SOEC interconnect (Cell-Connex™) manufacturer & supplier)

The Cell-Connex™ fuel cell interconnects are made of Crofer 22APU / 22H or other SOFC / SOEC dedicated ferritic steel (K41X, K44X, etc.). As they are grooved with a chemical milling process, any fine micro-structure and pattern design can be manufactured. Cell-Connex™ are ideal for stack prototyping. They are delivered with/out protective layer (NiO, MnCo2O4 or CuMn2O4 ) to avoid chromium evaporation and electrode poisoning (Fiaxell is for SOFC / SOEC interconnect (Cell-Connex™) manufacturer & supplier)

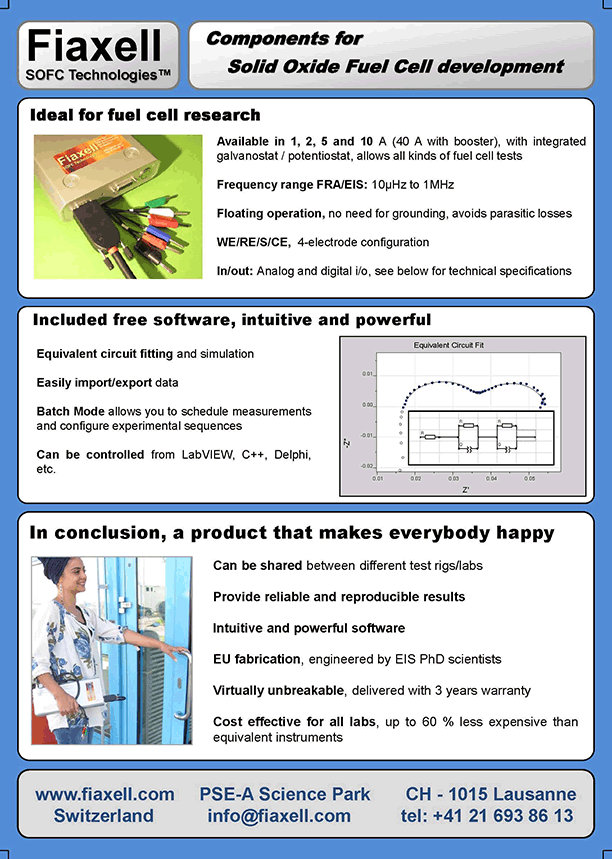

For SOFC / SOEC research, the use of an impedance spectrometer-EIS (or frequency analyser-FRA) is of most importance. Impedance spectroscopy and frequency analysis allow to separate the serial resistance from the electrolyte to the polarisation losses of the electrodes. With a reference electrode, cathode and anode can be separated. It is also useful for other research area as solar, PV, photovoltaics, battery, redox flow batteries, wet electro-chemistry, corrosion, electro-plating and PEFC, PEM, AFC, MCFC fuel cell (Fiaxell is supplier for impedance spectrometer & frequency analyzer (EIS / FRA))

For SOFC / SOEC research, the use of an impedance spectrometer-EIS (or frequency analyser-FRA) is of most importance. Impedance spectroscopy and frequency analysis allow to separate the serial resistance from the electrolyte to the polarisation losses of the electrodes. With a reference electrode, cathode and anode can be separated. It is also useful for other research area as solar, PV, photovoltaics, battery, redox flow batteries, wet electro-chemistry, corrosion, electro-plating and PEFC, PEM, AFC, MCFC fuel cell (Fiaxell is supplier for impedance spectrometer & frequency analyzer (EIS / FRA))

The impedance spectrometer (EIS-FRA) is available with voltage of ± 10 V and current of 1, 2, 5, or 10 amps with booster of 40 & 100 A. The frequency range is from 50 mHz up to 1 MHz. The software allows for batch mode, equivalent circuit fitting (smooth curves) and simulation. Bode & Nyquist plot are easily exportable to Zview and Zplot for instance. Floating or grounded hardware with 4 electrodes configuration WE / RE / S / CE. Cost effective and 3 years of warranty. Ideal for SOFC /SOEC and all fuel cell impedance spectroscopy measurement

The impedance spectrometer (EIS-FRA) is available with voltage of ± 10 V and current of 1, 2, 5, or 10 amps with booster of 40 & 100 A. The frequency range is from 50 mHz up to 1 MHz. The software allows for batch mode, equivalent circuit fitting (smooth curves) and simulation. Bode & Nyquist plot are easily exportable to Zview and Zplot for instance. Floating or grounded hardware with 4 electrodes configuration WE / RE / S / CE. Cost effective and 3 years of warranty. Ideal for SOFC /SOEC and all fuel cell impedance spectroscopy measurement

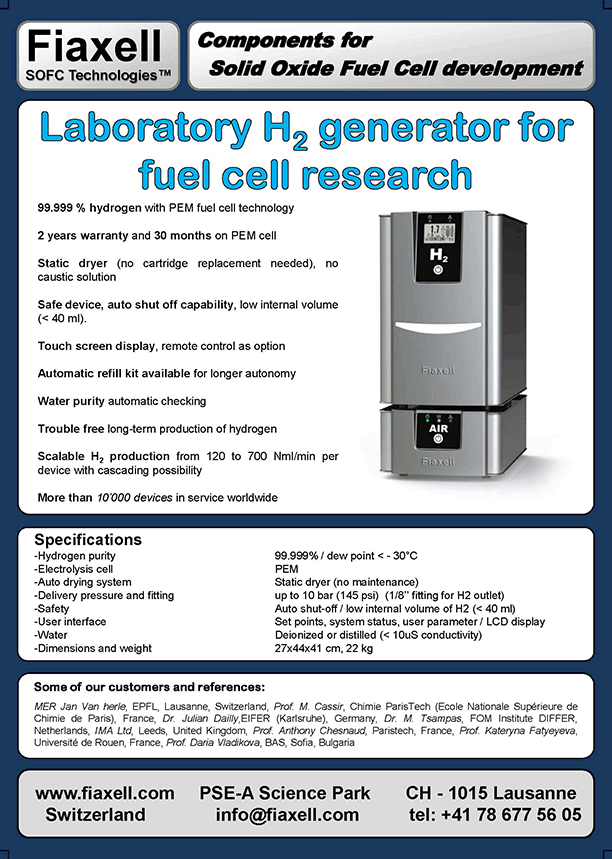

Our reliable hydrogen generator is providing H2 with 99.999 % purity (or 99.9999 % with PSA option) and 120 up to 1300 ml/min with 10 bar of pressure. It uses a static dryer to avoid the change of costly cartridge. Modules for pure air & nitrogen (N2, O2) are available. It is robust, long lasting (warranty of 3 years) and designed for replacing gas cylinder in lab. Ideal for feeding all fuel cell as SOFC /SOEC / PEM / PEFC / AFC. For analytical chemistry, the 99.9999 % generated H2 suits for FID mass spectroscopy & gas chromatography (Fiaxell is supplier for hydrogen, pure air & nitrogen generator)

Our reliable hydrogen generator is providing H2 with 99.999 % purity (or 99.9999 % with PSA option) and 120 up to 1300 ml/min with 10 bar of pressure. It uses a static dryer to avoid the change of costly cartridge. Modules for pure air & nitrogen (N2, O2) are available. It is robust, long lasting (warranty of 3 years) and designed for replacing gas cylinder in lab. Ideal for feeding all fuel cell as SOFC /SOEC / PEM / PEFC / AFC. For analytical chemistry, the 99.9999 % generated H2 suits for FID mass spectroscopy & gas chromatography (Fiaxell is supplier for hydrogen, pure air & nitrogen generator)

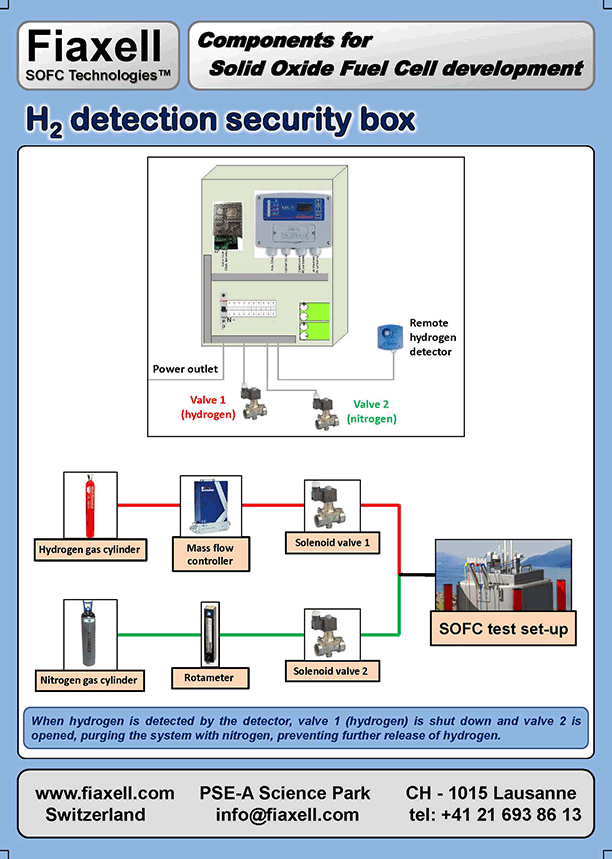

A complete gas detection security system is provided. It uses individual and remote detectors for each gases to detect hydrogen (H2), methane (CH4), carbon monoxide (CO), hydrogen sulfur (H2S) etc. The security box has different levels of alarm. When the gas concentration reaches a defined limit of safety, a valve close the gas line whereas nitrogen start to purge the SOFC / SOEC / PEM fuel cell test bench. All the wished sequences of events are scheduled through the control box panel (Fiaxell is supplier for H2, CH4 ,H2S gas detection and security in lab)

A complete gas detection security system is provided. It uses individual and remote detectors for each gases to detect hydrogen (H2), methane (CH4), carbon monoxide (CO), hydrogen sulfur (H2S) etc. The security box has different levels of alarm. When the gas concentration reaches a defined limit of safety, a valve close the gas line whereas nitrogen start to purge the SOFC / SOEC / PEM fuel cell test bench. All the wished sequences of events are scheduled through the control box panel (Fiaxell is supplier for H2, CH4 ,H2S gas detection and security in lab)

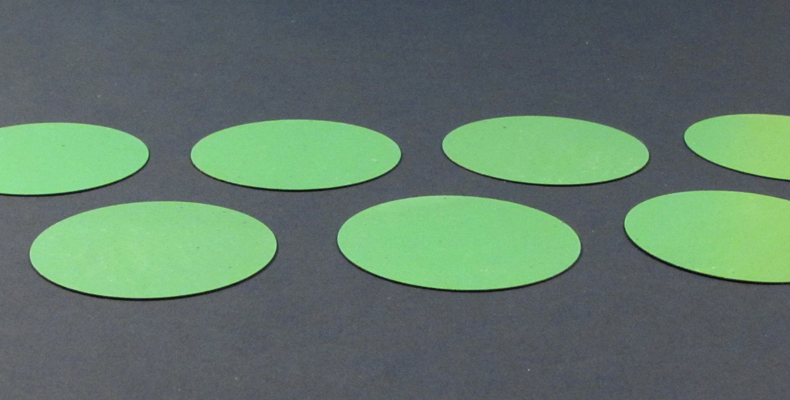

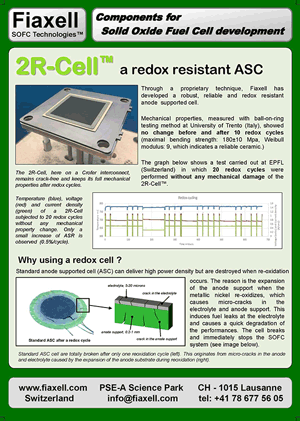

2R-Cell™ have been engineered to bring one more security factor to SOFC / SOEC system. It is a protection against fuel supply failure and cell peripheral re-oxidation that can lead to fatal stack destruction. Standard anode supported cell (ASC) can deliver high power density but are destroyed when re-oxidation occurs. 2R-Cell gives the security of first generation electrolyte supported cell (ESC) with electrical performance of ASC. 2R-Cell can withstand redox cycles without any change in the mechanical properties (Fiaxell is manufacturer & supplier for redox anode supported cell (ASC) and electrolyte supported cells (ESC))

2R-Cell™ have been engineered to bring one more security factor to SOFC / SOEC system. It is a protection against fuel supply failure and cell peripheral re-oxidation that can lead to fatal stack destruction. Standard anode supported cell (ASC) can deliver high power density but are destroyed when re-oxidation occurs. 2R-Cell gives the security of first generation electrolyte supported cell (ESC) with electrical performance of ASC. 2R-Cell can withstand redox cycles without any change in the mechanical properties (Fiaxell is manufacturer & supplier for redox anode supported cell (ASC) and electrolyte supported cells (ESC))

The 2R-Cell™ SOFC / SOEC redox resistant cell is fabricated with very standard material such as nickel oxide (NiO) and zirconia (8YSZ & 3YSZ). The cell are particularly suited in electrolyzer for water and CO2 co-electrolysis as they can withstand very low concentration of hydrogen (H2) and/or carbon monoxide (CO) without being destroyed by re-oxidation. Standard 2R-Cell™ are equipped with LSCF / LSCF-GDC composite cathode and a GDC buffer layer to prevent La & Sr diffusion in the zirconia electrolyte. 2R-Cell™ have been tested is stack configuration at the Swiss institute of Technology (EPFL) for few hundreds of hours

The 2R-Cell™ SOFC / SOEC redox resistant cell is fabricated with very standard material such as nickel oxide (NiO) and zirconia (8YSZ & 3YSZ). The cell are particularly suited in electrolyzer for water and CO2 co-electrolysis as they can withstand very low concentration of hydrogen (H2) and/or carbon monoxide (CO) without being destroyed by re-oxidation. Standard 2R-Cell™ are equipped with LSCF / LSCF-GDC composite cathode and a GDC buffer layer to prevent La & Sr diffusion in the zirconia electrolyte. 2R-Cell™ have been tested is stack configuration at the Swiss institute of Technology (EPFL) for few hundreds of hours

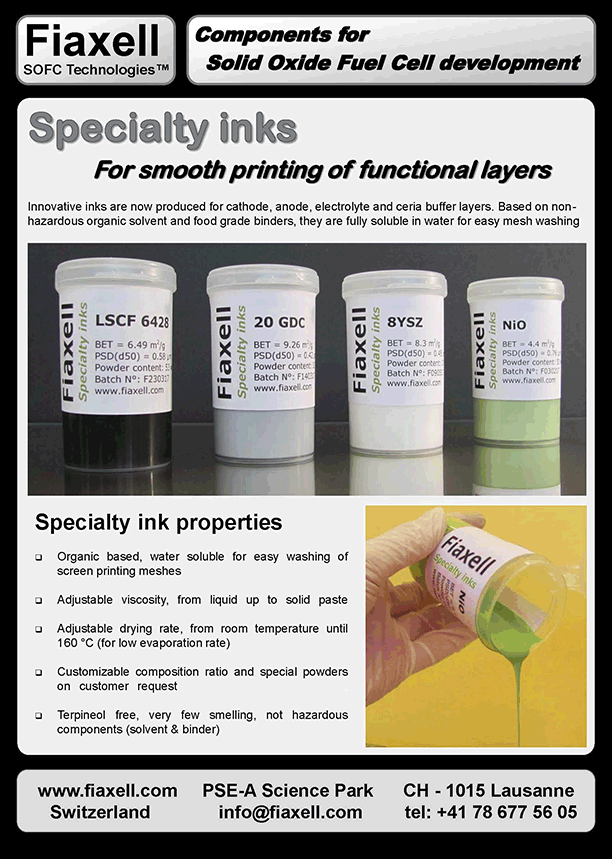

The specialty inks have been developed for screen printing, tape casting and spray drying. Slurry compositions have been optimized for SOFC / SOEC fuel cell substrate, thin electrolyte, buffer layer, electrode, cathode, anode and interconnect protective layer. The ceramic inks & pastes are made with NiO, 3YSZ, 8YSZ, ScSZ, LSCF, LSC, GDC, CuMn2O4, Co2MnO4, BCY, BCZY powders. All organic solvents and binders are soluble in water for easy screen-printing frame cleaning. Water based slurries are available for tape casting and experimental formulation for screen-printing (Fiaxell is manufacturer & supplier for SOFC / SOEC cathode, anode, electrolyte & buffer layer inks, slurry or paste)

The specialty inks have been developed for screen printing, tape casting and spray drying. Slurry compositions have been optimized for SOFC / SOEC fuel cell substrate, thin electrolyte, buffer layer, electrode, cathode, anode and interconnect protective layer. The ceramic inks & pastes are made with NiO, 3YSZ, 8YSZ, ScSZ, LSCF, LSC, GDC, CuMn2O4, Co2MnO4, BCY, BCZY powders. All organic solvents and binders are soluble in water for easy screen-printing frame cleaning. Water based slurries are available for tape casting and experimental formulation for screen-printing (Fiaxell is manufacturer & supplier for SOFC / SOEC cathode, anode, electrolyte & buffer layer inks, slurry or paste)

The Fiaxell specialty inks for SOFC / SOEC research are extensively customizable. Their viscosity can be adjusted from liquid like up to solid paste. The ink can be formulated for a wide range of drying rate, from room temperature conditions up to low vapor pressure needing an oven drying step at 160 °C. Fiaxell specialty inks allow for thin layer deposition and < 3 microns of ceria protective layer (GDC, SDC etc.) are reproducibly screen printed. To control the shrinkage of the electrolyte during sintering, inks with coarser powders are provided. Other electrolyte material as ScSZ for high conductivity, BCZY for protonic conductor or exotic formulation are prepared on demand

The Fiaxell specialty inks for SOFC / SOEC research are extensively customizable. Their viscosity can be adjusted from liquid like up to solid paste. The ink can be formulated for a wide range of drying rate, from room temperature conditions up to low vapor pressure needing an oven drying step at 160 °C. Fiaxell specialty inks allow for thin layer deposition and < 3 microns of ceria protective layer (GDC, SDC etc.) are reproducibly screen printed. To control the shrinkage of the electrolyte during sintering, inks with coarser powders are provided. Other electrolyte material as ScSZ for high conductivity, BCZY for protonic conductor or exotic formulation are prepared on demand

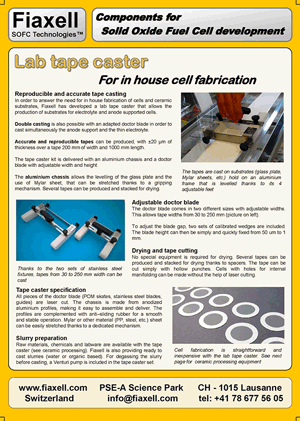

Our lab tape caster has been developed to answer the need for in house fabrication of SOFC / SOEC cells and ceramic / metallic substrates (electrolyte and anode supported cell ESC, ASC). Our manual tape casting equipment allows to quickly cast, dry and sinter the samples needed for electro-chemical characterization. Accurate thickness from 5 µm up to 1 mm of the ceramic tapes are reproducibly cast. Tolerances of less than 10 µm are obtained on large tape of 200 X 1000 mm. The doctor blade allows casting width from 50 up to 230 mm. Double layer (thin YSZ or GDC electrolyte below thick NiO-YSZ substrate) can also be cast. For degassing the slurry before casting, a Venturi pump is included in the tape caster set. Fiaxell is also providing ready to cast water or organic based slurries (Fiaxell is manufacturer and supplier for lab tape caster and slurry to cast electrolyte or anode)

Our lab tape caster has been developed to answer the need for in house fabrication of SOFC / SOEC cells and ceramic / metallic substrates (electrolyte and anode supported cell ESC, ASC). Our manual tape casting equipment allows to quickly cast, dry and sinter the samples needed for electro-chemical characterization. Accurate thickness from 5 µm up to 1 mm of the ceramic tapes are reproducibly cast. Tolerances of less than 10 µm are obtained on large tape of 200 X 1000 mm. The doctor blade allows casting width from 50 up to 230 mm. Double layer (thin YSZ or GDC electrolyte below thick NiO-YSZ substrate) can also be cast. For degassing the slurry before casting, a Venturi pump is included in the tape caster set. Fiaxell is also providing ready to cast water or organic based slurries (Fiaxell is manufacturer and supplier for lab tape caster and slurry to cast electrolyte or anode)

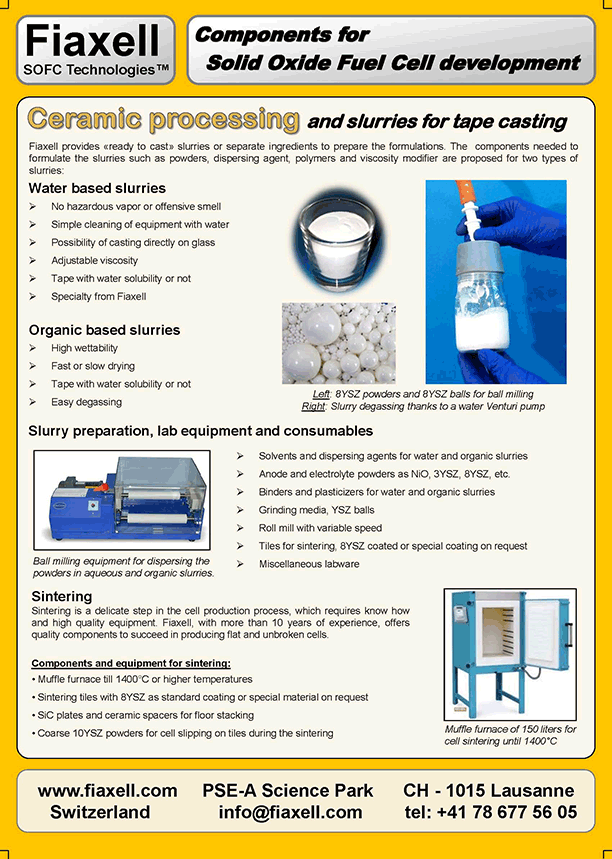

Ceramic processing is the core business of Fiaxell and we whish to offer our customers the possibility to create their best SOFC / SOEC ceramic or metallic cells (electrolyte, anode or metallic supported cells, ESC, ASC, MSC). For this purpose we are providing all useful powders (NiO, YSZ, LSM,LSCF, LSC, GDC, BCY, BCZY, CuMn2O4), slurries, inks, binder (water or organic based), lab equipment for dispersion preparation, degassing, casting and sintering (roll milling machine, zirconia ceramic balls, venturi pump, lab tape caster and high temperature muffle furnace). The ceramic processing assortment is also useful for other ceramic research area as electro, piezzo, ferro-electric, super-conductivity, capacitor, dielectric and glass tape casting for gasket and sealing. Fiaxell is manufacturer for 8YSZ coated ceramic tiles and supplier for muffle furnace, roll mill and all ceramic for SOFC /SOEC processing.

Ceramic processing is the core business of Fiaxell and we whish to offer our customers the possibility to create their best SOFC / SOEC ceramic or metallic cells (electrolyte, anode or metallic supported cells, ESC, ASC, MSC). For this purpose we are providing all useful powders (NiO, YSZ, LSM,LSCF, LSC, GDC, BCY, BCZY, CuMn2O4), slurries, inks, binder (water or organic based), lab equipment for dispersion preparation, degassing, casting and sintering (roll milling machine, zirconia ceramic balls, venturi pump, lab tape caster and high temperature muffle furnace). The ceramic processing assortment is also useful for other ceramic research area as electro, piezzo, ferro-electric, super-conductivity, capacitor, dielectric and glass tape casting for gasket and sealing. Fiaxell is manufacturer for 8YSZ coated ceramic tiles and supplier for muffle furnace, roll mill and all ceramic for SOFC /SOEC processing.