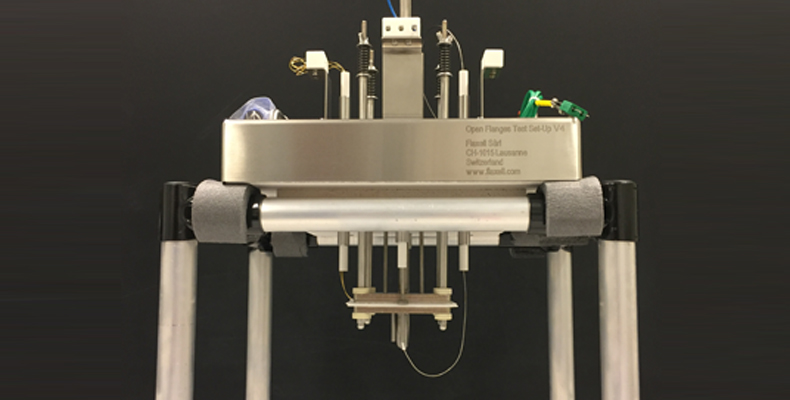

Open Flanges™ test Set-up

One single solid oxide fuel cell tester for all SOFC / SOEC button cell tests

As manufacturer and supplier, Fiaxell is proposing a flexible SOFC / SOEC button cell test fixture that offers the following advantages:

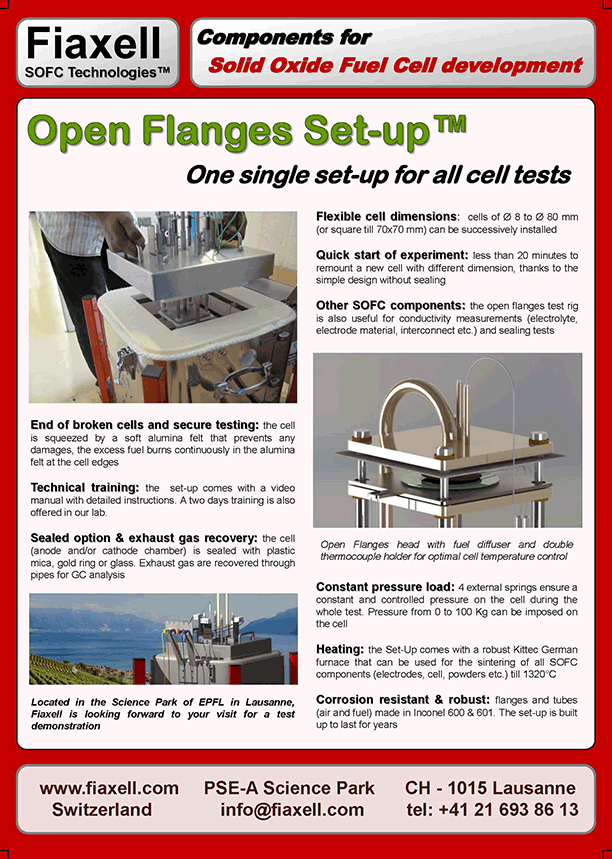

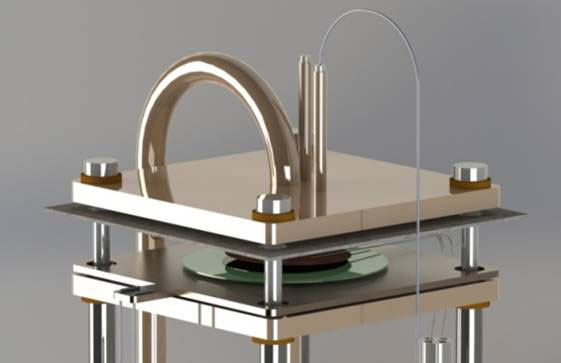

Inserting the Open Flanges test fixture in the furnace for fuel cell and/or electrolysis (SOFC / SOEC) experiments

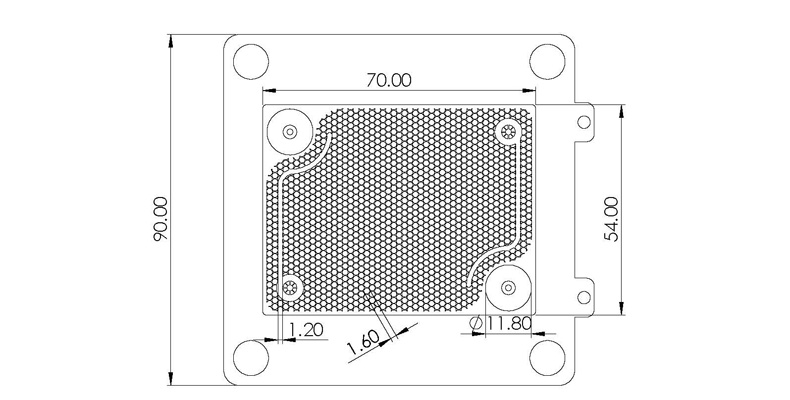

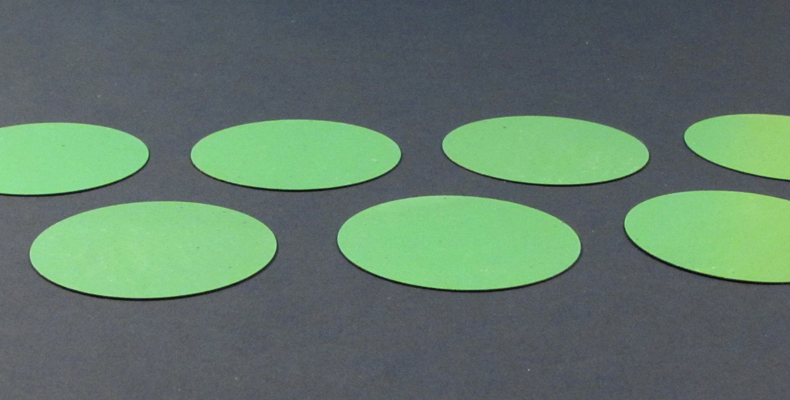

Inserting the Open Flanges test fixture in the furnace for fuel cell and/or electrolysis (SOFC / SOEC) experimentsFlexible cell dimensions and shape: from one to the other experiment, small pellet to medium size circular or square cell can be installed in the SOFC / SOEC button cell test stand. Test equipment for larger SOFC / SOEC cells of 100 X 100 mm will be soon in our catalogue

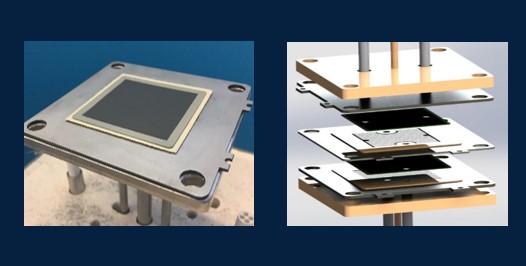

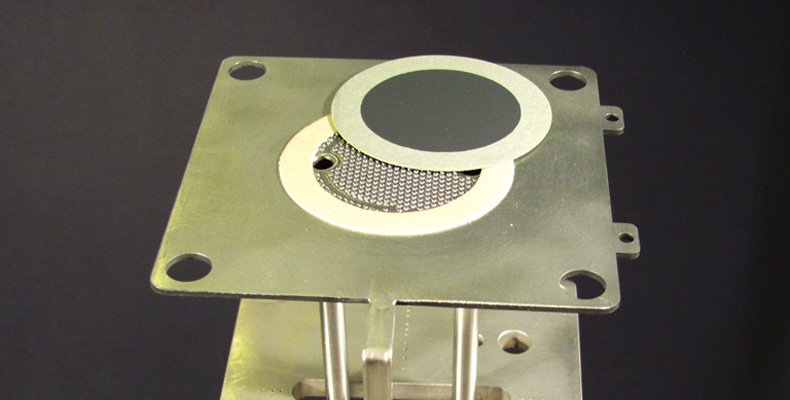

Quick start of experiment: less than 20 minutes to remount a new cell with different dimension and shape. Thanks to its proprietary head design, the SOFC / SOEC button test station allows button cell testing with or without gasket (open flange test mode or with exhaust gas recovery)

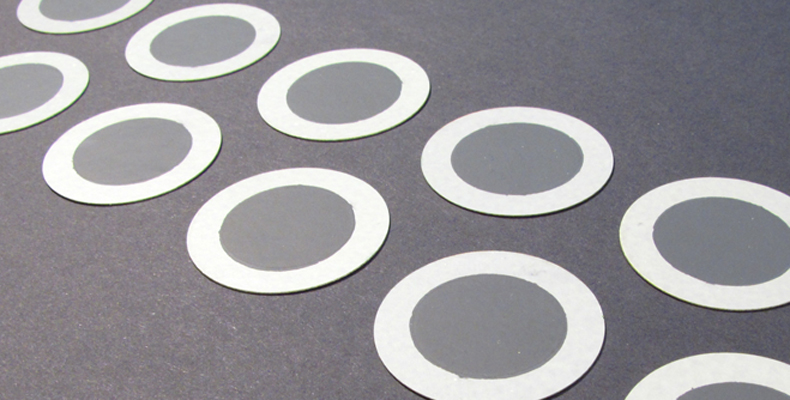

Other SOFC components: the button cell test rig is also useful for conductivity measurements (SOFC / SOEC electrolyte, electrode material, interconnect etc.) and sealing tests (glass, mica gold ring etc.)

End of broken cells: fragile and unperfect cell can also be mounted in the the SOFC / SOEC test set-up head. In this case, the cell is squeezed beteween soft alumina felts that prevents any damages. Quick made lab prototype cells (ASC / ESC) can thus be directly evaluated in the SOFC / SOEC button cell tester before material improvement

Technical training: the SOFC / SOEC button cell test fixture comes with a video manual with all detailed instructions sorted by experiment titles. A two days training is also offered in our lab. For years now, researchers in the field of solid oxide fuel cell & electrolyzer from universities around the world are meeting in our lab and exchanging scientific knowledge about fuel cell testing and fabrication

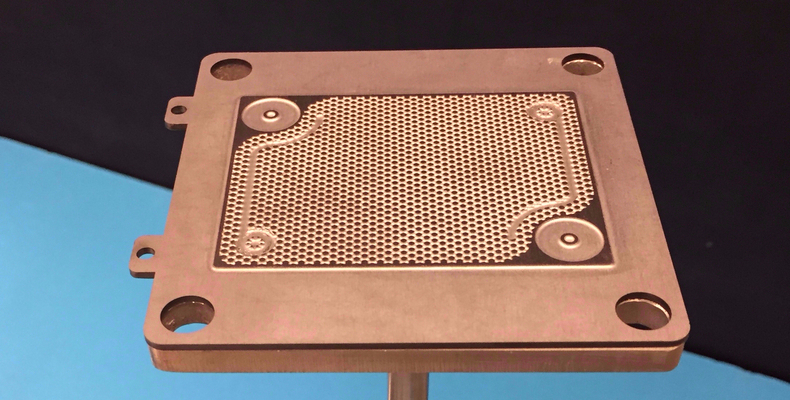

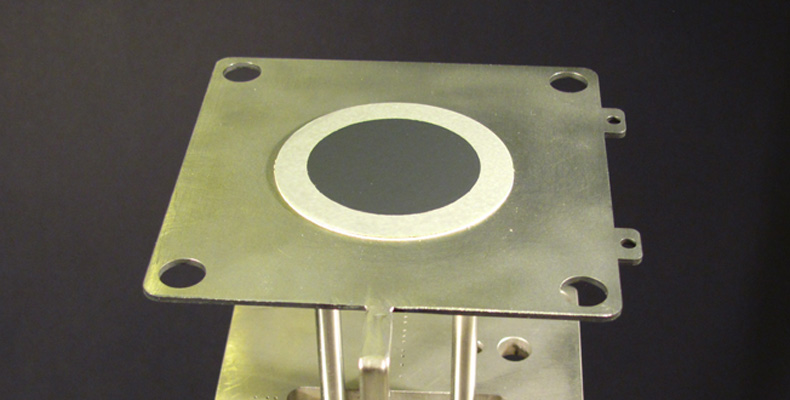

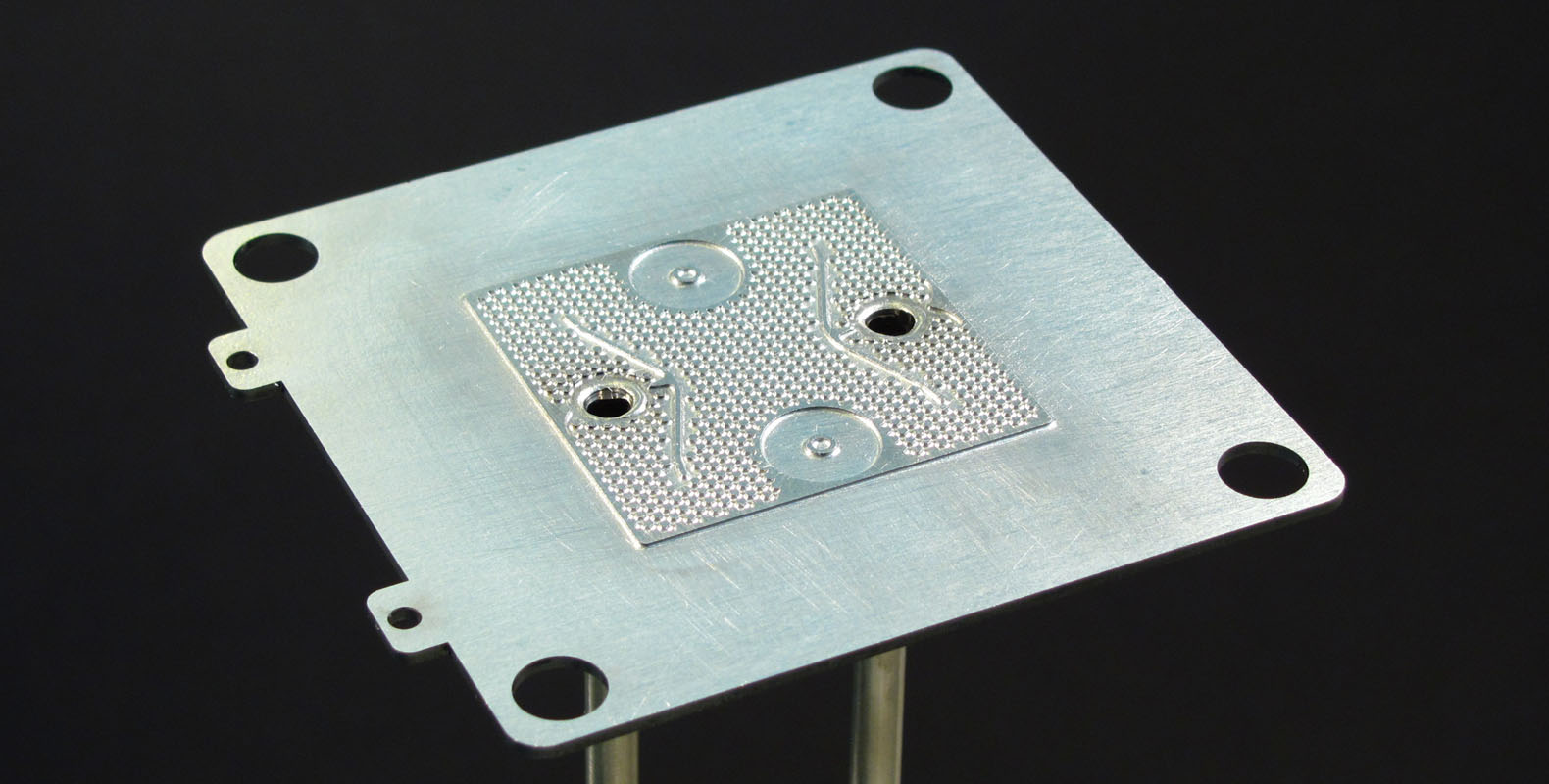

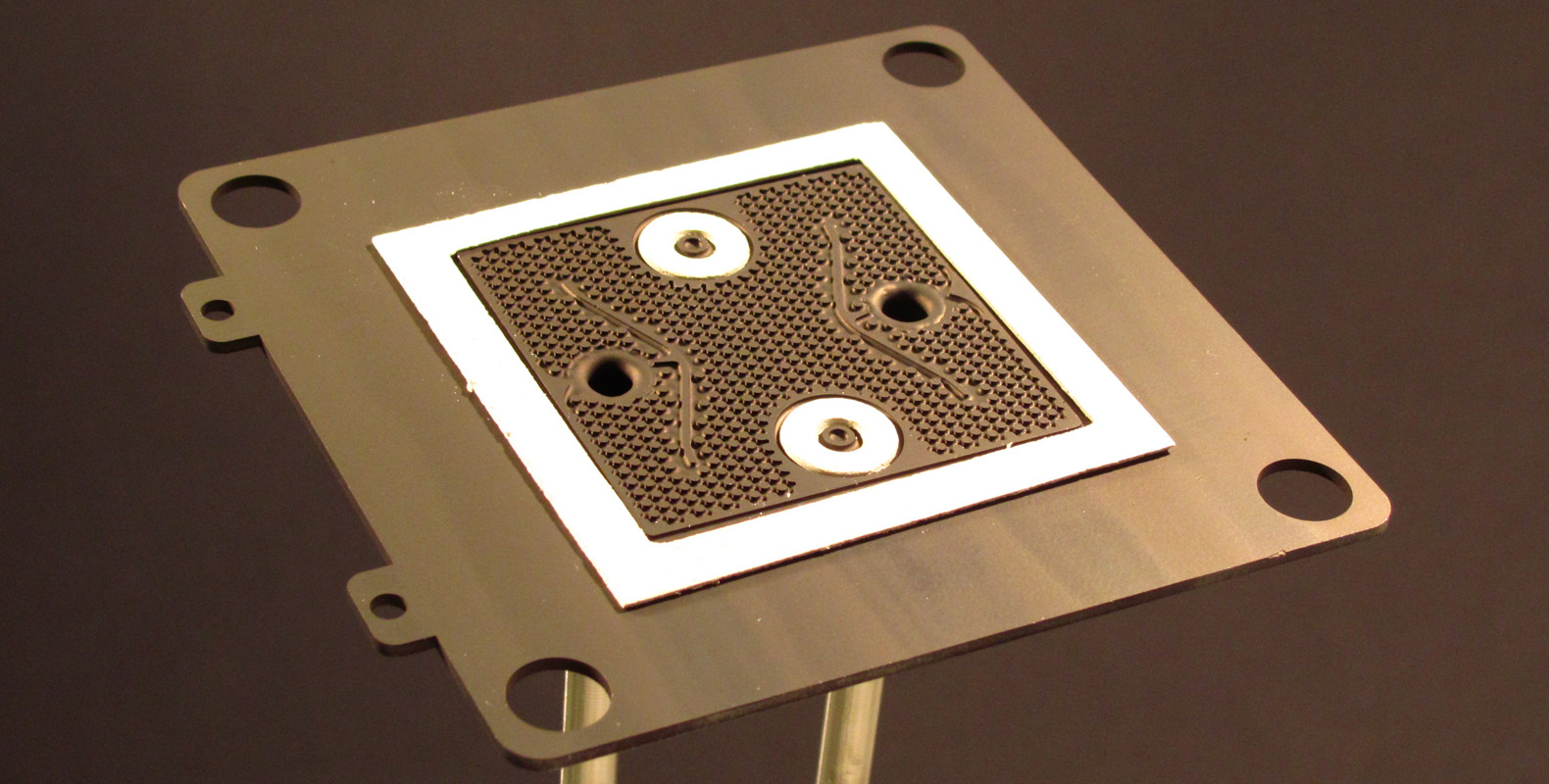

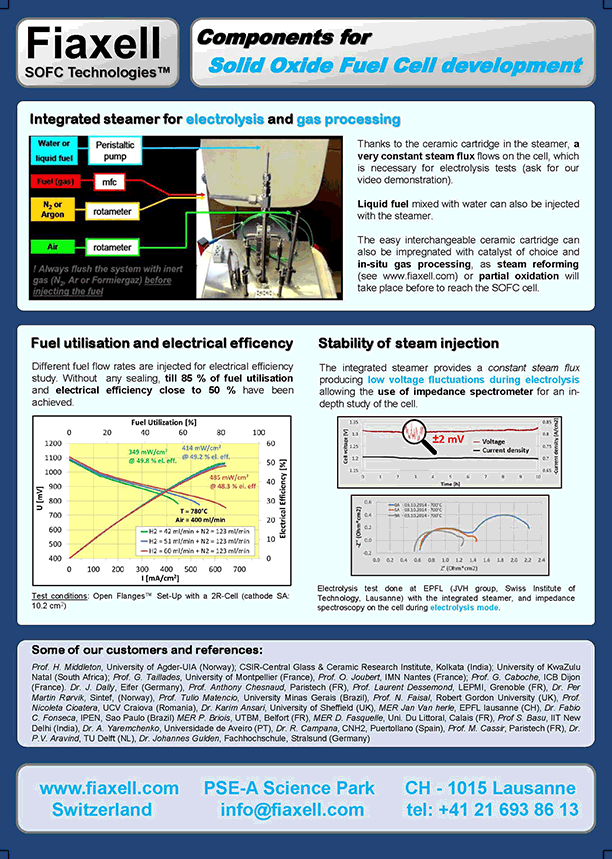

Open Flanges head with fuel diffuser and double thermocouple holder for optimal cell temperature control

Open Flanges head with fuel diffuser and double thermocouple holder for optimal cell temperature control

Sealed option & exhaust gas recovery: the cell (anode and / or cathode chamber) is sealed with soft and deformable mica, gold ring or glass. Exhaust gas are recovered through pipes for GC analysis. It is particularly important during H2O, CO2 co-electrolysis in order to measure the amount of H2 and CO generated

Constant pressure load: 4 external calibrated springs ensure a constant and controlled pressure on the cell during the whole experiement. Pressure range from naught to > 100 Kg can be chosen and imposed to the cell in our SOFC / SOEC test bench.

Heating: the Set-Up comes with a robust Kittec German furnace that can be used for the sintering of all SOFC / SOEC components (electrodes, cell, powders etc.) up to 1320°C

Corrosion resistant & robust: flanges and tubes (air and fuel) made in Inconel 600 & 601. Our SOFC / SOEC button cell test fixture is built up to last for years

Fiaxell is the manufacturer and supplier of the SOFC / SOEC Open Flanges™ button cell tester. The test fixture is highly flexible and allows a wide range of SOFC / SOEC experiments (see below short stack, long term, small ceramic pellets test kit)

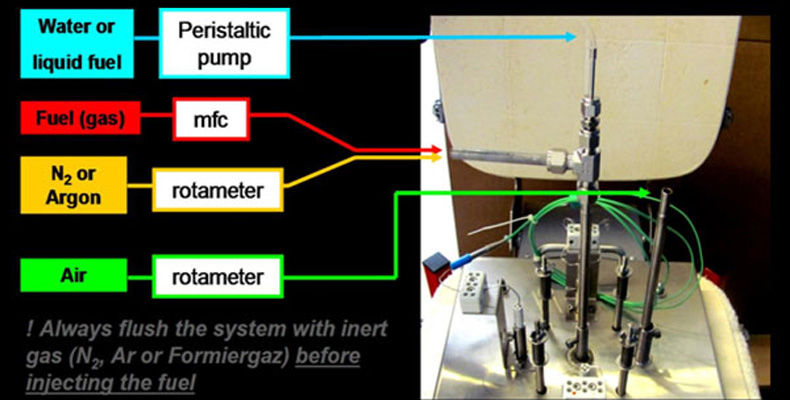

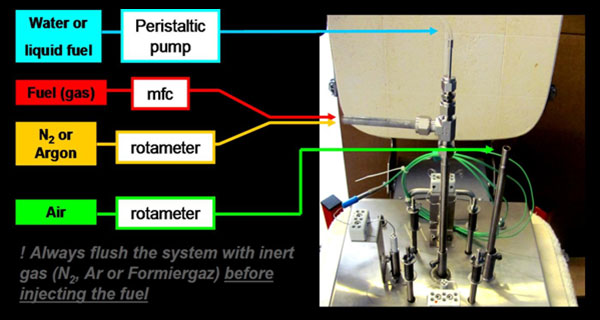

Integrated steamer for electrolysis and gas processing

Thanks to a proprietary and optimized steamer design, a very constant steam flux flows on the cell, which is necessary for water electrolysis tests (ask for our video demonstration)

Thanks to this integrated steamer, the SOFC test station can instantly be transformed into a SOEC electrolyzer that produces hydrogen

When feeding the SOFC / SOEC test station with H2O and CO2, co-electrolysis providing hydrogen and carbon monoxide will take place

Liquid fuel (ethanol, methanol, ammonia, gazoline etc.) mixed with water can also be injected with the integrated steamer of our SOFC / SOEC test rig

The optimized design of our integrated steamer allows to load it with catalyst of choice and in-situ gas processing, as steam reforming (SR) or partial oxidation (POX) will take place before to reach the SOFC / SOEC cell. Furthermore, the temperature reading and gas sampling for GC analysis can take place in the whole gas processing zone.

The Open Flanges™ SOFC / SOEC button cell test station is thus offering a complete turnkey solution for all gas processing analysis and investigations

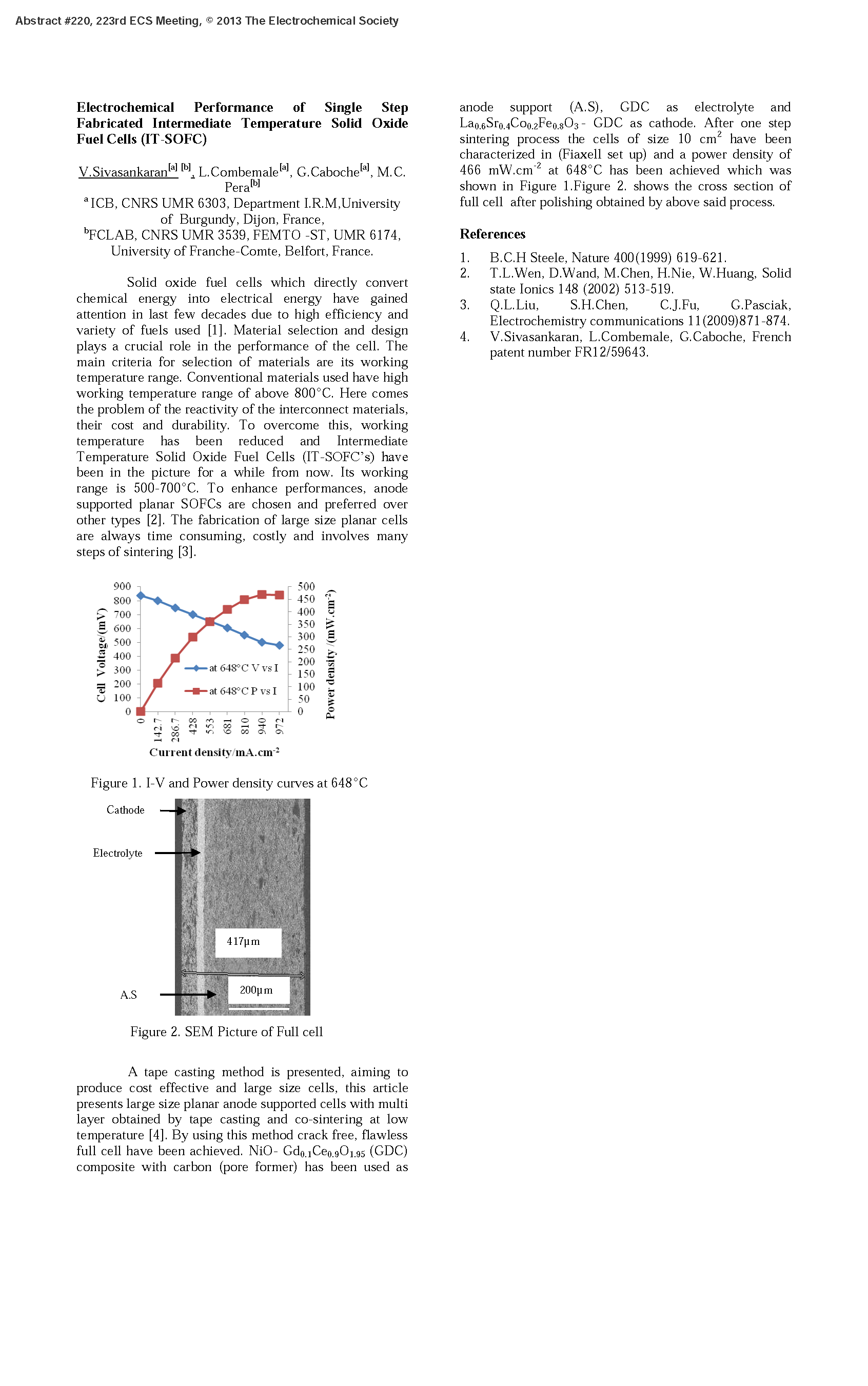

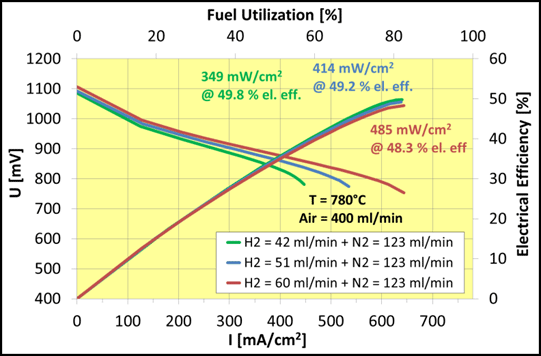

Fuel utilisation and electrical efficiency

Different fuel flow rates are injected for electrical efficiency study. Without any sealing (Open Flanges test mode), until 85 % of fuel utilisation and electrical efficiency close to 50 % have been achieved.

Test conditions: Open Flanges™ Set-Up with a 2R-Cell (cathode SA: 10.2 cm2). The fuel utilization scale only refers to the red curves (H2 = 60 ml/min).

Test conditions: Open Flanges™ Set-Up with a 2R-Cell (cathode SA: 10.2 cm2). The fuel utilization scale only refers to the red curves (H2 = 60 ml/min).Stability of steam injection

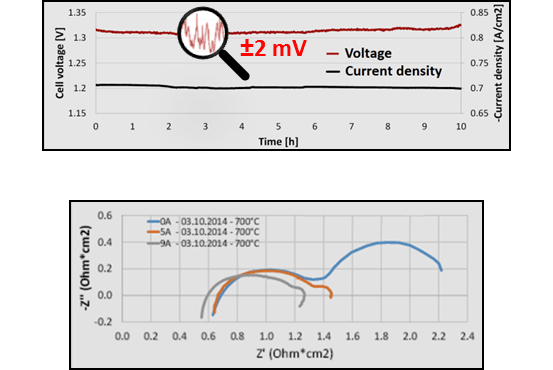

The integrated steamer provides a constant steam flux producing low voltage fluctuations during electrolysis allowing the use of impedance spectrometer (FRA) for an in-depth study of the SOFC / SOEC cell.

Water electrolysis SOEC test done at EPFL (JVH group, Swiss Institute of Technology, Lausanne) with the integrated steamer, and impedance spectroscopy (FRA) on the cell during electrolysis mode.

Water electrolysis SOEC test done at EPFL (JVH group, Swiss Institute of Technology, Lausanne) with the integrated steamer, and impedance spectroscopy (FRA) on the cell during electrolysis mode.Kits for the Open Flanges™ SOFC / SOEC button cell tester:

Fiaxell, as manufacturer and supplier has developed different test kits that are directly integrable on the SOFC / SOEC Open Flanges™ test bench:

- Short stack kit: for an easy study of each SOFC / SOEC stack parameters

- Tubular ceramic kit for protonic SOFC / SOEC button cell testing

- Long term test kit: to avoid any chromium or other contaminants in the electrodes during SOFC / SOEC long term test (>1000 hours)

- Small pellets testing kit: ideal for SOFC / SOEC thick and small ceramic pellets characterisation in different atmospheres

Download the brochure:

Click on the picture to download the SOFC / SOEC button cell tester technical data sheet or click here to go to all Fiaxell prospectus

Some of our customers and references:

Prof. H. Middleton, University of Agder-UIA (Norway); CSIR-Central Glass & Ceramic Research Institute, Kolkata (India); University of KwaZulu Natal (South Africa); Prof. G. Taillades, University of Montpellier (France), Prof. O. Joubert, IMN Nantes (France); Prof. G. Caboche, ICB Dijon (France). Dr. J. Dally, Eifer (Germany), Prof. Anthony Chesnaud, Paristech (FR), Prof. Laurent Dessemond, LEPMI, Grenoble (FR), Dr. Per Martin Rørvik, Sintef, (Norway), Prof. Tulio Matencio, University Minas Gerais (Brazil), Prof. N. Faisal, Robert Gordon University (UK), Prof. Nicoleta Cioatera, UCV Craiova (Romania), Dr. Karim Ansari, University of Sheffield (UK), MER Jan Van herle, EPFL lausanne (CH), Dr. Fabio C. Fonseca, IPEN, Sao Paulo (Brazil) MER P. Briois, UTBM, Belfort (FR), MER D. Fasquelle, Uni. Du Littoral, Calais (FR), Prof S. Basu, IIT New Delhi (India), Dr. A. Yaremchenko, Universidade de Aveiro (PT), Dr. R. Campana, CNH2, Puertollano (Spain), Prof. M. Cassir, Paristech (FR), Dr. P.V. Aravind, TU Delft (NL), Dr. Johannes Gulden, Fachhochschule, Stralsund (Germany)

See also the customer references presented in the reference website page.

The Open Flanges Set-Up in the literature:

2017

2017_-_Physico-Chemical_Characterisation_of_CSFIC_-_C._B._Njoku_P._G._Ndungu_SOFC_XV.pdf

2017_-_Physico-Chemical_Characterisation_of_CSFIC_-_C._B._Njoku_P._G._Ndungu_SOFC_XV.pdf 2017_-_Nanoparticles_Infiltration_into_SOFC_Cathode_Backbones_-_Julian_Dailly_Mathieu_Marrony_-_SOFC_XV.pdf

2017_-_Nanoparticles_Infiltration_into_SOFC_Cathode_Backbones_-_Julian_Dailly_Mathieu_Marrony_-_SOFC_XV.pdf 2017_-_Effect_of_Surfactants_on_the_Physico-Chemical_Charact._of__IrO-CeSmO_-_Chima_B.Njoku_G._Ndungu_-_SOFC_XV.pdf

2017_-_Effect_of_Surfactants_on_the_Physico-Chemical_Charact._of__IrO-CeSmO_-_Chima_B.Njoku_G._Ndungu_-_SOFC_XV.pdf 2017_-_Corrugated_Electrode-Electrolyte_Interfaces_in_SOFC_-_A._Chesnaud_A._Thorela_-_SOFC_XV_-_Mines_Paristech.pdf

2017_-_Corrugated_Electrode-Electrolyte_Interfaces_in_SOFC_-_A._Chesnaud_A._Thorela_-_SOFC_XV_-_Mines_Paristech.pdf 2017_-_Advanced_Proton_Conducting_Ceramic_Cell_as_Energy_Storage_Device_-_M._Marrony_and_J._Dailly_-_SOFC_XV.pdf

2017_-_Advanced_Proton_Conducting_Ceramic_Cell_as_Energy_Storage_Device_-_M._Marrony_and_J._Dailly_-_SOFC_XV.pdf 2017 - Influence of the Bias Substrate Power on the GDC Buffer Layer - E. Breaz, P. Briois - SOFC XV.pdf

2017 - Influence of the Bias Substrate Power on the GDC Buffer Layer - E. Breaz, P. Briois - SOFC XV.pdf

2016

2015

2015_-_Steam_and_Co-electrolysis_Sensitivity_Analysis_on_Ni-YSZ_Supported_Cells_-_G._Rinaldi_J._Van_herle.pdf

2015_-_Steam_and_Co-electrolysis_Sensitivity_Analysis_on_Ni-YSZ_Supported_Cells_-_G._Rinaldi_J._Van_herle.pdf 2015_-_Electrochemical_study_of_a_SOFC_fuelled_with_various_gaseous_mixtures_-_A._Le_Gal_La_Salle_A._Subrenat.pdf

2015_-_Electrochemical_study_of_a_SOFC_fuelled_with_various_gaseous_mixtures_-_A._Le_Gal_La_Salle_A._Subrenat.pdf 2015_-Investigation_of_2R-cell_Degradation_Under_Thermal_Cycling_and_RedOx_Cycling__S._Diethelm_J._Van_herle_-_SOFC_XIV.pdf

2015_-Investigation_of_2R-cell_Degradation_Under_Thermal_Cycling_and_RedOx_Cycling__S._Diethelm_J._Van_herle_-_SOFC_XIV.pdf 2015 - Study of 2R-Cell Equipped with LSC and LSCF Cathodes under Thermic and Redox Cycl. - Carolina Grize, Vaibhav.pdf

2015 - Study of 2R-Cell Equipped with LSC and LSCF Cathodes under Thermic and Redox Cycl. - Carolina Grize, Vaibhav.pdf

2013